Configurable Equipment

Configurable Robotic Palletizer

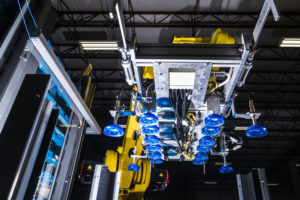

Automatic palletizing can have a significantly positive impact on your packaging operation. Since manual palletizing is often the most injury-prone part of the packaging process, automating the process reduces downtime and the risk of injuries associated with heavy lifting. Pearson designs its palletizing and de-palletizing cells with built-in flexibility for future pattern changes and rapid changeovers. They are easy to operate and require minimal maintenance to perform at exceptional levels. Sturdy steel frames and heavy-duty construction withstand heavy use and loads, even in caustic environments. Every manufacturing process is different, from products to physical space, so your machinery should be designed to your requirements. Relying on over thirty years of robotic integration and packaging automation experience, Pearson Packaging Systems will tailor your new robotic palletizers to overcome your unique manufacturing challenges and enhance your operation lastingly.

Cut Costs With Automated Palletizers

Operational efficiencies are all about cutting costs and increasing production throughput. In the ongoing struggle to combat supply chain pressures and maintain healthy margins, automation plays a vital role and robotic palletizers are a key component.

- Increased speed: Being at the end of the packaging line, the palletization can become a bottleneck if it cannot keep up with the product flow upstream. Automating this process will enable your operation to keep up with the throughput demands.

- Reduce injuries: Palletizing is a notorious source for injuries from constant lifting and bending. An automatic palletizer will protect your workers and your company from unnecessary L&I claims.

- Reduced labor costs: Our robotic palletizer can work around the clock. It does not require breaks, stacks pallets faster than most people can, and won’t get tired or sick. And instead of rising wages, your per hour cost will only go down.

Robotic Palletizers Configured to Your Needs

Automating your palletizing operation is a big undertaking. To ensure that the end result provides you with all the benefits you hoped for, we will dive deep into understanding your unique palletization requirements, challenges and limitations. Together with your Pearson sales manager and application engineer, we will gather detailed information to optimize your palletizer. The following list is not exhaustive but provides a good overview of some of the details we like to understand.

- Case/Product information: We will need to know what type of case or product you are running such as RSC, HSC, Bags or trays. How many different SKU’s do you want the machine to handle? Per SKU, we will need dimensions, weight, type of seal and case rate. In addition, we will ask you about how the product enters the robotic palletizer.

- Pallet information: To build your desired pallet patterns, we need to understand what they look like, how many you have, if you require pallet sheets or layer sheets, what type of pallets you use (GMA, ChEP or HT), their weight and dimension.

- Production environment: Important aspects for us to know are: your ambient temperature to evaluate if the robotic palletizer will need heat or cooling support, if there are any physical obstructions, your ceiling heights, and what your concrete thickness is; to adequately support the robot and production flow and discharge heights.

- Built-in capabilities: Do you need automatic pallet dispensing, stretch wrapping or any other extended capability?

- Specification requirements: Does your company have specific technical requirements for guarding, electrical or air?

What Are You Palletizing?

- RSC or HSC corrugated cases and cartons

- Bliss boxes and trays

- Bags

- Pails and drums

- Bundles

- Bottles and jugs

How Are You Stacking?

- Individual cases, rows, or entire layers

- Column-stacked, interlocked or pin-wheel configurations, mixed loads, or variable patterns

- With or without slip and tier sheets

- Integrated stretch wrappers, pallet labelers, and other third party OEM equipment

Yes? Then Let's Talk!

Robotic palletization offers distinct advantages over conventional methods including smaller footprint, multi-tasking ability, flexibility to accommodate changes in product or pallet patterns and automatic tool changeovers. While conventional palletizers have their place in extremely high-speed and low variability applications, Pearson Packaging Machinery focuses exclusively on robotic palletizers.

With almost 30 years of solving robotic palletization needs, we have seen just about every application possible. Through the acquisition of Flexicell, the longest established robotic integrator focused on end-of-line palletization, we are not just one of the many ‘industry leaders’ but can honestly claim unrivaled experience.

Work With the Expert in Robotic Palletizing!

The following is an overview of the expertise and capabilities we have acquired over three decades of robotic palletization work. Your application is in good hands.

- Slow to medium-speed case and row palletizers, high-speed full layer palletizers and depalletizers

- Ability to meet rigorous requirements of food grade, sanitary, washdown, freezer, and high humidity environments

- Experience with a wide variety of pallet patterns including column-stacked, interlocked or pin-wheel configurations, mixed loads or variable pattern placement programming

- Availability of low level or high level infeed options

- Accurate sorting of cases from single infeed to multiple outfeeds using barcodes

- Insertion of slip sheets and single or multiple tier sheets to steady the product on the pallet

- Pallet handling using conveyors, transfer carts, and automated or autonomous guided vehicles

- Safety guarding to include options such as fencing, light curtains or area sensors

- Application-specific end-of-arm tools optimized to guarantee product quality and pallet stability with optional automatic tool changeover

- Four- to six-axes robots, selected to meet the specific application (speed, product weight and size)

- Integration of stretch wrappers, pallet labelers and other third party OEM equipment

- Easy-to-use Human Machine Interface supported by our proprietary User Centric Design including the ability to restrict access depending on authority level

- Easy-to-use Pallet Configuration Tool to quickly create, modify, copy or clear new pattern recipes on the HMI or adjust parameters such as case or pallet height, number of layers, pick/drop speeds or delays during production

- PackML standardized programing language to ease integration and servicing

Solve Your Robotic Palletizing Needs With Pearson Packaging Systems

The benefits of automated robotic palletizing can be considerable, if implemented well. Pearson Packaging Systems is committed to your success. Improve the efficiency of your manufacturing operation and reduce costs to help you see a fantastic ROI within a few years. Get started on the process by requesting a quote for your robotic palletizer, and we'll work with you to design your ideal machinery. If you have any questions about our equipment, contact us and we'll be in touch.

Not just a good product but a reliable partner

- Expect a rugged machine design optimized for durability and long equipment life in a 24/7 environment

- Benefit from a uniform user interface for your erecting, packing, sealing, and palletizing equipment

- Count on comprehensive sales, aftermarket, and service support

- Experience premier industry lead-times for faster delivery and shorter down-payment cycles

- Optimally support a high-turnover labor force with the most advanced Human Machine Interface (HMI) in the secondary packaging industry

- Rely on extensively trained and FANUC Certified technicians to service your equipment including FANUC robots

- Have confidence in reliable, thought-out solutions based on 60 years of erecting, packing and sealing and 30 years of robotic integration experience

- Depend on our team of project managers to provide ongoing visibility to meet delivery timelines and budgets

- Always lean on us for 24/7 live service support

- If CapEx is unavailable, but automation should not be delayed, talk to us about our Machine-as-a-Service program