Increasingly, Pearson customers are needing packing solutions that can accommodate vertical product patterns per the requirements of the big box retailers they supply to. So what’s the best way to get your products into display-ready cases that can go from shipping container to store shelf with minimal human labor? Below is a comparison of our most common, tried-and-true vertical packing solutions.

______________________________________________________________________________________

Rotating Bucket

Ideal Application

– Lay-flat or gussetted bags (from small/thin to large/heavy), single-serve snack bags, cartons, and more

– Low-mid-high speed lines

– Lines running minimal SKUs

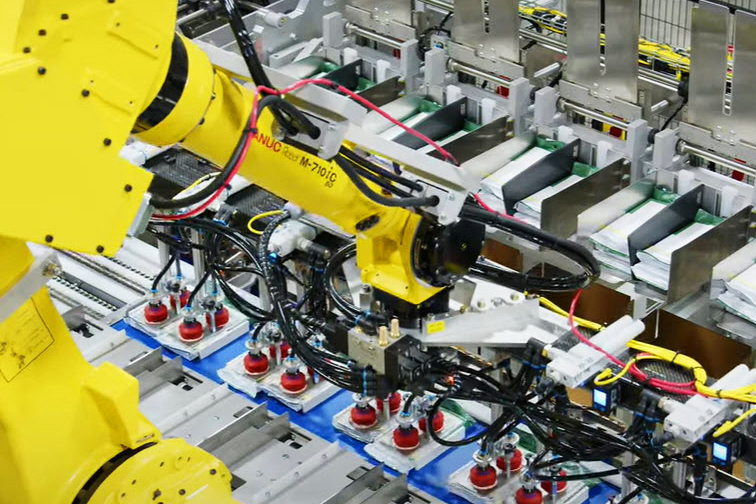

How it Works

Upstream robot(s) form product patterns on the conveyor (or collating conveyors may be used depending on SKU count) and downstream robot(s) pick and place products horizontally into bucket(s). The buckets clamp and rotate, placing products vertically into the cases below.

Benefits/Considerations

– Easily and affordably scalable using extended tooling and multiple buckets (vs. multiple robots)

– Comparatively smaller footprint than multi-robot solutions

– Multi-SKU changeovers can be time consuming with tool + bucket adjustments

Robot-Held Case

Ideal Application

– Lay-flat or gussetted bags (from small/thin to large/heavy), single-serve snack bags, cartons, and more

– Low-mid-high speed lines

– Lines running multiple SKUs

How it Works

Upstream robot(s) form product patterns on the conveyor and downstream robot(s) hold and position cases at a loading station. Products are cross-pushed via a mechanical plate into the awaiting cases. The robot rotates the filled case(s) upright and places them on the exit conveyor.

Benefits/Considerations

– Scalable with multiple robots

– Cost-competitive compared to stainless steel or washdown rotating bucket applications

Catcher’s Mitt

Ideal Application

– Flat, non-slippery bag or sachet products, ideally with minimal product shifting

– Lower-speed applications

– Lines running multiple SKUs

How it Works

Upstream robot(s) form product patterns on the conveyor and downstream robot(s) move to “catch” products in bin-style tool (stacked orientation) at the end of the product conveyor. The tool clamps and rotates to place products vertically into the cases below.

Benefits/Considerations

– Speed requirements may be limiting, although the solution is scalable with multiple robots

_____________________

Ready to explore the right vertical case packing solution for your operation? Contact Us.