With two Pearson palletizers already operating in the field, this Pennsylvania-based dairy manufacturer was ready to automate their third line after labor shortages peaked during the Covid pandemic.

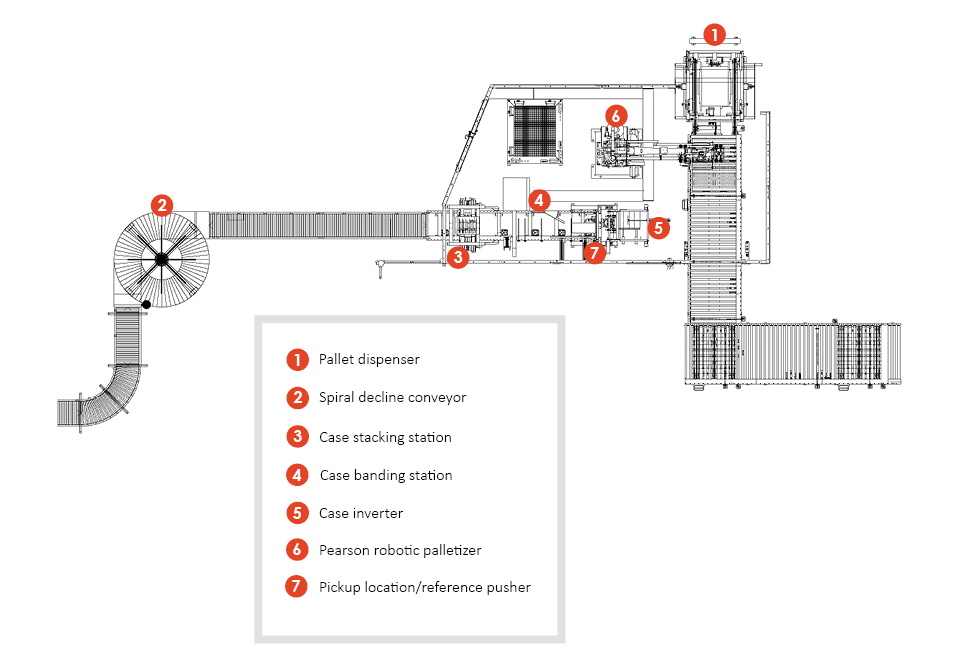

With the goal of maximizing their pallet capacity to save shipping costs, they needed a robotic solution that could stack, band, and upright their long, flat case styles to be vertically-palletized. They also needed the flexibility to run traditional RSCs through the cell to be stacked in a variety of horizontal patterns.