This West Coast-based specialty meats manufacturer needed to improve the case forming portion of their bagged jerky line. Manually forming rollover cases was a cumbersome, injury-prone, and time consuming task that was hindering production and becoming increasingly challenging with ongoing labor shortages.

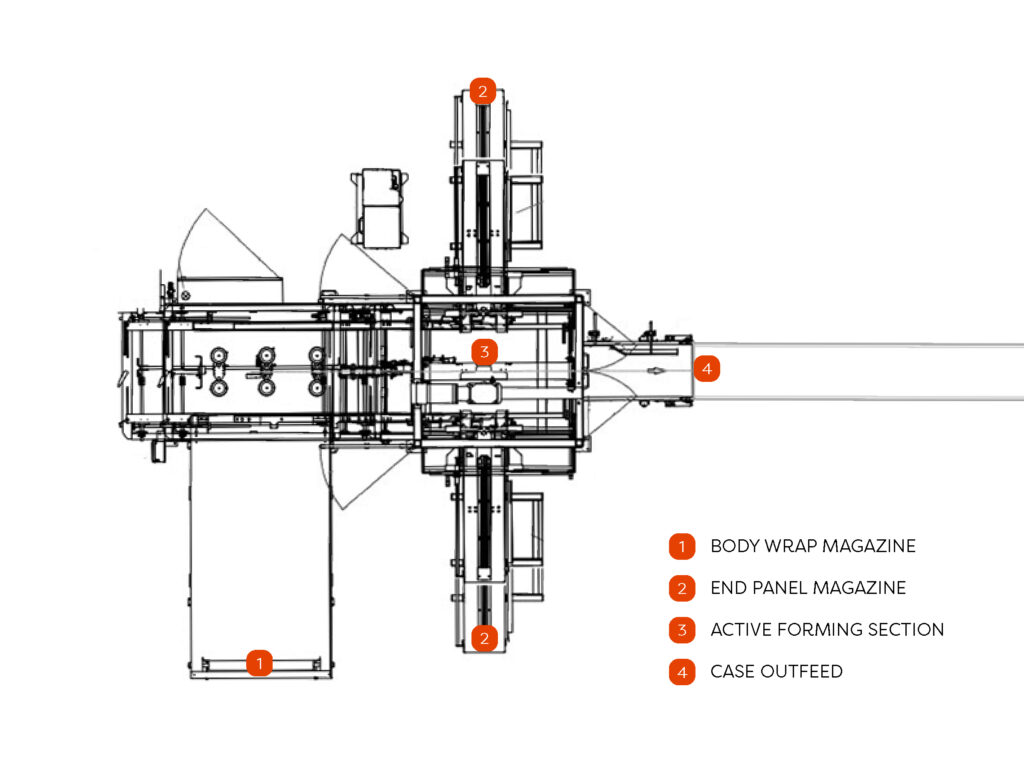

The manufacturer adopted a new bliss display case that could be automatically produced on Pearson bliss forming equipment. The boxes met Costco’s supplier requirements, with a 4-window display to allow customers access from all sides, and triangular corners to ensure product protection and stacking strength.