Automatic Case Packing of Cartons of Snack Cakes

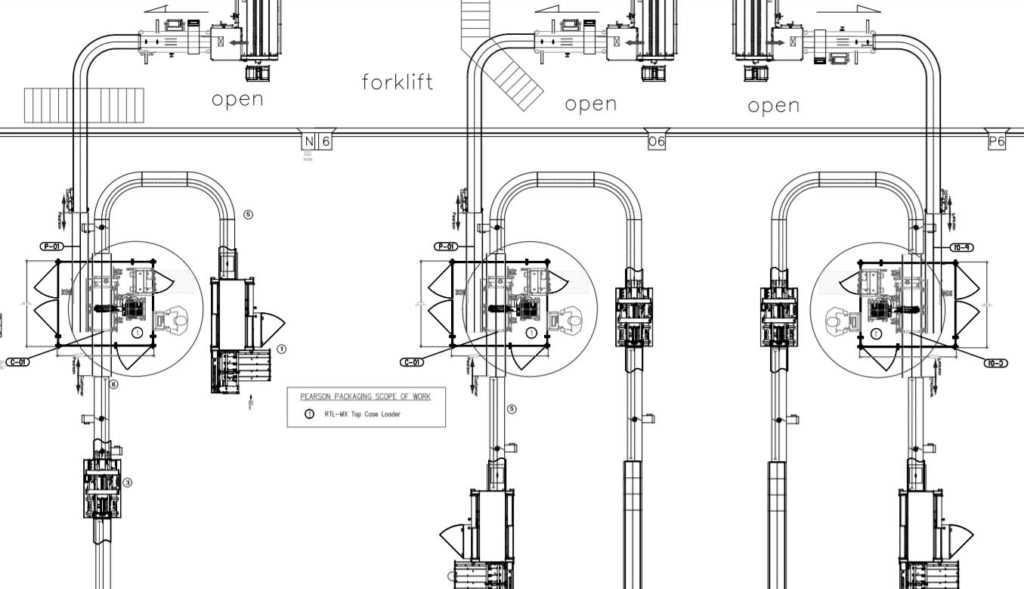

- Application: Deploying reconfigured cases and pack patterns to improve pallet space utilization. The project replaces three 7yr old Pearson case packers with new RTL-MX models.

- Speed: 30-66 products per minute, 4 different product and pack configurations

- ROI Justification: The reconfigured cases increased pallet space utilization by 14%. Higher throughput demands further required an upgrade from a single pick to a dual pick and although FANUC’s M10 robots could have handled the application, the upgraded M20 robots offer greater long-term flexibility.

- Important to Customer: Short lead times, which Pearson proactively managed by ordering a batch of 32 Fanuc robots ahead of actual customer purchases to combat pandemic related supply chain delays.

Solved with Pearson’s RTL-MX

Optimized for Demanding 24/7 Operations

To reduce overall transportation costs, this customer wanted to roll out reconfigured shipping cases and pack patterns that would allow 10 additional cases to fit on each pallet (an increase of 14%). Increased throughput demands also induced a need to pick two cartons at a time, instead of the previous single pick. Since they only had a short window to stop production for installation and start-up, the customer opted against an aftermarket upgrade that would have taken too long to tear down and rebuild the equipment. And although FANUC’s M10 robots used in their previous Pearson top-load case packer could have handled the application, the upgraded M20 robots offered much greater long-term flexibility due to their higher speed, payload and reach capacity. With a dedicated installation window in mind, the customer was very concerned about implementing the cost savings measure as soon as possible. To combat the pandemic related supply chain delays and support our customers with more desirable lead times, Pearson proactively purchased large batches of robots ahead of customer purchase commitments.

Cartons of snack cakes are being received from the upstream equipment in a single lane, broad side leading. A product clamp facilitates the accumulation of a group of products, which is then indexed forward for the robot to pick. In the meantime, cases enter the cell. Once two cases arrive, flap control lowers above the case’s score lines to avoid snagging of products during the placement into the box. The robot then picks the group of products and loads them into the cases in a smooth motion. After the case is full, the flap control raises and the cases advance out of the cell, while the next two cases proceed to the loading station.

RTL-MX Capabilities

- Application: Top Load Case Packing

- Case Support: Chipboard Cartons, Corrugated Cases, Bliss Boxes, Trays, and Warehouse Totes

- Supported Pack Patterns: Vertical, Horizontal, Interleaved, Stacked, On Edge, On End, Rainbow or Variety Packs, Bulk and Shelf-Ready

- Speed: Application specific up to 1,500 products/min

- Controls: FANUC PMC | AB CompactLogix PLC | PanelView Color HMI

- Operation:

- Robotically using multi-axis articulated robot with MTBF of over 80,000 hours and flexibility to accommodate product changes or variations

- Application specific product handling and transfer such as servo-collating, diverting, tabletop, mat top and independent cart technology

- Vision guidance and line tracking to inspect, detect, sort and manipulate products on the fly or balance the load between robots

- Continuous case motion design for higher speed applications and reduced wear

- Application-specific end-of-arm tool with optional automatic tool changeover

- Programming Language: PackML

Minimized Total Cost of Ownership

- Robotic Operation takes advantage of high mean between failure of 80,000 hrs, reduced parts count and wear

- Standard remote access capability for efficient technical support and extensive service cost savings

- HMI models web experience for quick familiarity, intuitive operation, reduced training needs and better upkeep of the equipment

- Tune-Up Plus Program ensures optimal uptime and controlled parts and service expenses year over year

Interested to learn more about this solution?

Click here to contact us today!