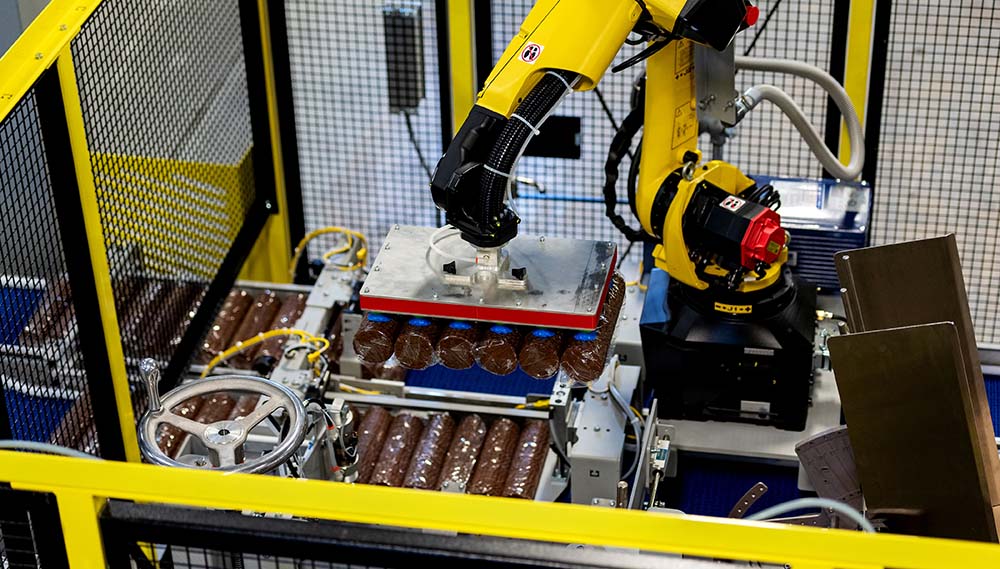

Case Packing of Flow-Wrapped Wafer Cookies

- Application: Loading several layers of multiple flow-wrapped tubes of round wafers into a case, separated by layer sheets

- Speed: 30-120 products per minute, 15-40 products per case, 7 different product and pack pattern variations

- ROI Justification: Lack of available labor that reliably shows up to work leads to unanticipated downtimes and production shortages straining the relationship with the end-customer using the wafers for their ice cream sandwiches. The automated solution will replace 4 workers / 3 shifts hand-packing wafers.

- Unique Challenges: Delicate wafers break easily

- Important to Customer: Reliability of the solution backed by a strong performance guarantee and on-time delivery during these supply chain battered times

Solved with Pearson’s RTL-MX

Optimized for Demanding 24/7 Operations

The wafer cookies come on a single lane. At the interface of the customer’s sleeving equipment and the first Pearson product conveyor, the wafers are transferred at a 90 degree and continue traveling wide side leading. After passing a metal detector, the wafer cookies enter the packer cell where they will be accumulated in the pick zone against an extended product stop. Once a complete layer of product has been accumulated the upstream product is being clamped to hold back line pressure while the downstream clamp relaxes to singulate the full layer. The robot then approaches the pick zone to gently acquire the product layer using high flow vacuum. At the same time, cases are being indexed into the machine to a fixed load station, which incorporates case guides to avoid any product snagging on the case lip. The robot then places the complete layer into the case and returns to the pick zone. Between layer placements, a MultiFeeder sheet dispenser releases a separation sheet on top of the product layer. The robot and sheet dispenser alternate until the case is full and indexed out of the system.

RTL-MX Specs

- Application: Top Load Case Packing

- Case Support: Chipboard Cartons, Corrugated Cases, Bliss Boxes, Trays, and Warehouse Totes

- Supported Pack Patterns: Vertical, Horizontal, Interleaved, Stacked, On Edge, On End, Rainbow or Variety Packs, Bulk and Shelf-Ready

- Speed: Application specific up to 1,500 products/min

- Controls: FANUC PMC | AB CompactLogix PLC | PanelView Color HMI

- Operation:

- Robotically using multi-axis articulated robot with MTBF of over 80,000 hours and flexibility to accommodate product changes or variations

- Application specific product handling and transfer including servo-collating, diverting, tabletop, mat top and independent cart technology

- Vision guidance and line tracking to inspect, detect, sort and manipulate products on the fly or balance the load between robots

- Continuous case motion design for higher speed applications and reduced wear

- Application-specific end-of-arm tool with optional automatic tool changeover

- Programming Language: PackML

Minimized Total Cost of Ownership

- Robotic Operation takes advantage of high mean between failure of 80,000 hrs, reduced parts count and wear

- Standard remote access capability for efficient technical support and extensive service cost savings

- HMI models web experience for quick familiarity, intuitive operation, reduced training needs and better upkeep of the equipment

- Tune-Up Plus Program ensures optimal uptime and controlled parts and service expenses year over year

Interested to learn more about this solution?

Click here to contact us today!