Video Library

On this page you find a comprehensive video library with numerous filter options. Search for videos highlighting particular machines, various applications or even specific types of products being run on the line.

Show all

Resource

Automation Application

Robotic Palletizing for Beverage Trays

This robotic palletizing cell picks and stacks rows of heavy trays filled with bottled beverages. Custom end-of-arm vacuum tooling is used to securely grip bottle tops.

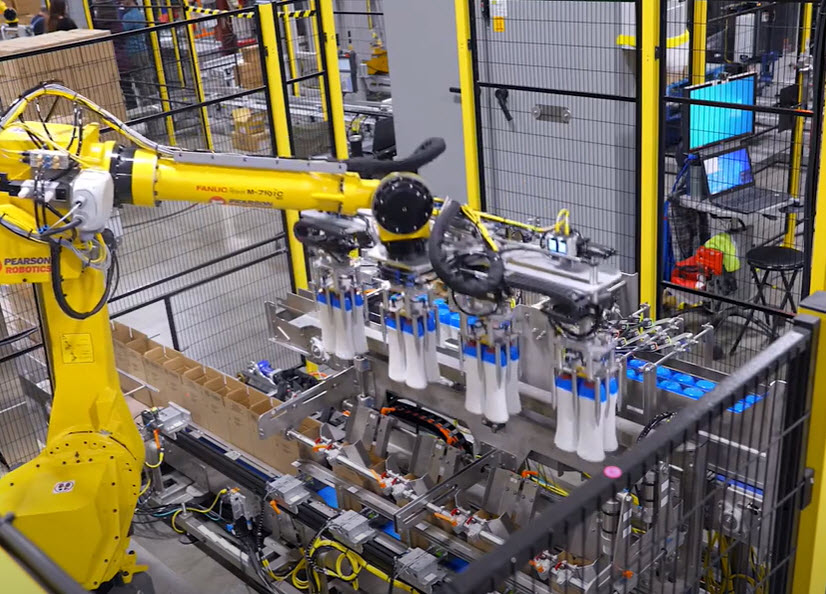

Robotic Palletizing for Stacks & Bundles of Paper Products

This robotic palletizing cell features dual palletizing stations for continuous operation. A FANUC robot uses a multi-functional end-of-arm tool to pick stacks of paper bags, wrapped bundles of paper products, and slip sheets.

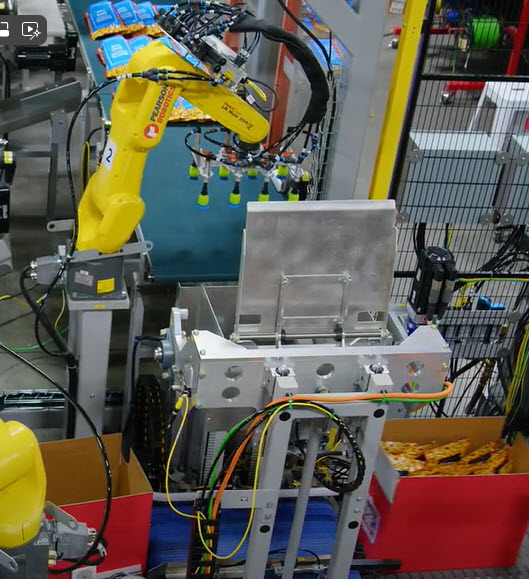

Horizontal & Vertical Robotic Packing for Bags of Snack Foods

This robotic packing application features a vision system to detect the orientation of snack bags, and multiple robots sharing the workload to form pack patterns, then pick/place products in horizontal and vertical orientations.

Robotic Vertical Case Packing for Bagged Vegetables

This robotic vertical case packer uses vision and line tracking to determine product orientation and a Scara robot to form pack patterns. At the end of the product conveyor, a second robot with a catcher’s mitt-style end-of-arm tool moves to collect the products, and clamps to hold the bags in place as it rotates, placing products into cases.

Robotic Case Packing for Plastic Bottles of Laundry Soap

This robotic case packer by Pearson Packaging Systems packs plastic bottles of laundry soap at a fast rate of speed. It incorporates a lane diverter to manage product flow into the cell, and a custom end-of-arm tool that elongates to pack into multiple cases at a time.

Robotic Palletizing for Cases of Bagged Syrup

This robotic palletizing cell features an automatic pallet dispenser, an activated roller belt sorter, and a high-payload FANUC robot with vacuum tooling designed to pick layers of cases weighing as much as 620+ lbs.

An intuitive HMI supports operation, changeovers and troubleshooting. Plus, the cell is also equipped with Remote Access capability.

BF30-G Bliss Former

Pearson’s BF30-G Bliss Former forms sturdy shipper and display-ready box styles at rates up to 30 cases per minute. This machine is ideal for larger boxes commonly found at club-style stores like Costco or Walmart.

An active forming section ensures boxes are secure and consistently square, while an intuitive HMI supports operation, changeovers and troubleshooting.

An optional high-capacity Automatic Stack Transfer System is available to decrease the frequency of consumable reloading.

Robotic Palletizing for Bags & Boxes of Pet Food

This robotic palletizing solution handles plastic base sheets, bags, and boxes using custom end-of-arm tooling. (4) FANUC robots share the workload across dual lines, and an intuitive HMI with a pallet configuration tool makes operation, recipe selection, and changeovers a breeze. Plus, the cell is equipped with Remote Access capability for quick troubleshooting and resolution if the need arises.

Erect, Pack & Seal for Bagged Tortillas

In this application, a Pearson Case Erector and Sealer form consistently square and securely sealed cases. A robotic case packer is designed with a vision system to detect the location of products, and dual Scara robots pack the products into cases. A 2-person handpack station is integrated for small-batch product runs.

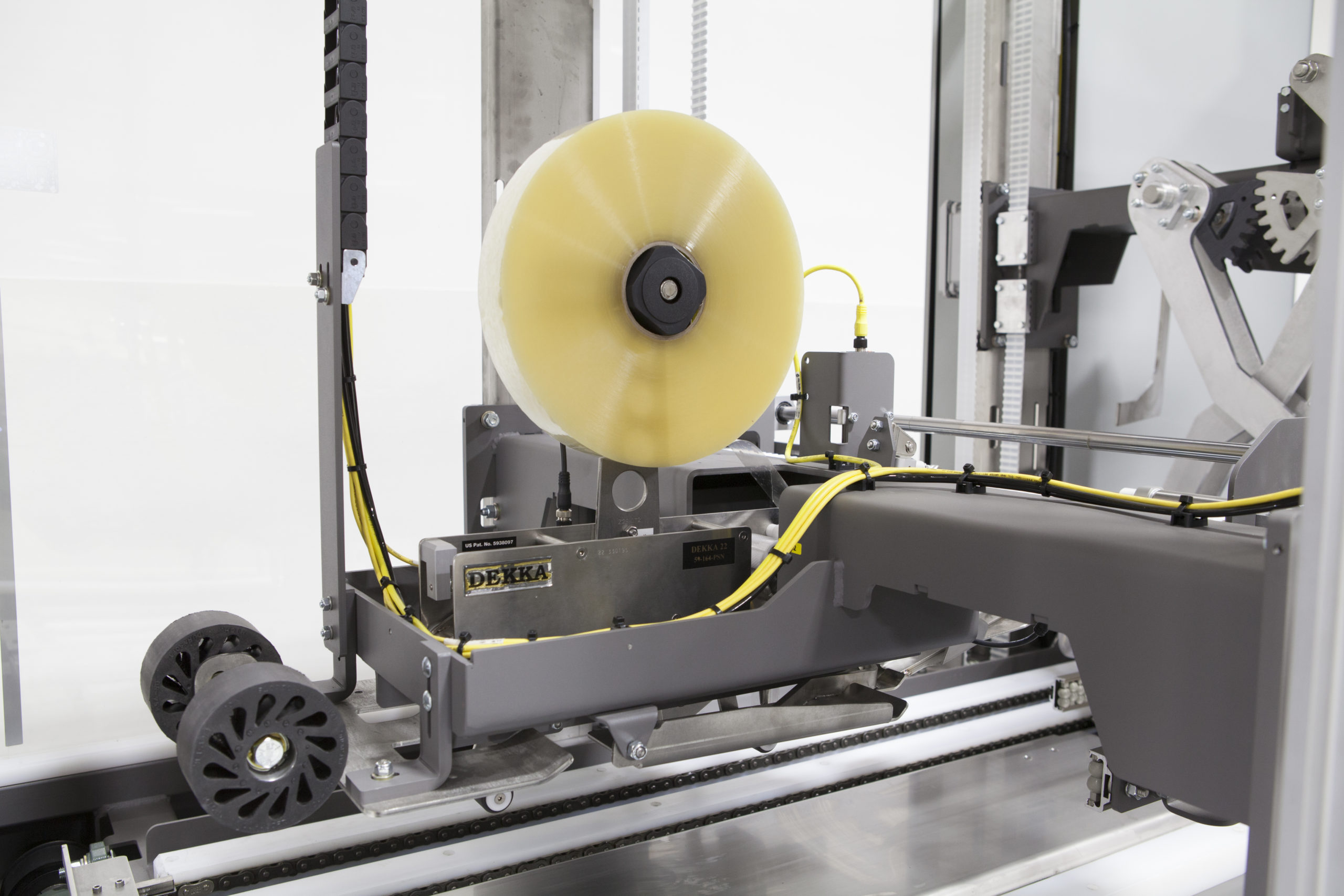

CS30-RT Case Sealer

Pearson’s CS30-RT Random Case Sealer offers top and bottom sealing capabilities at high speeds of up to 30 cases per minute. Every case that is introduced into the machine is being measured in height and width to automatically position the folding and sealing mechanism.