Erect

Insert

Pack

Seal

Palletize

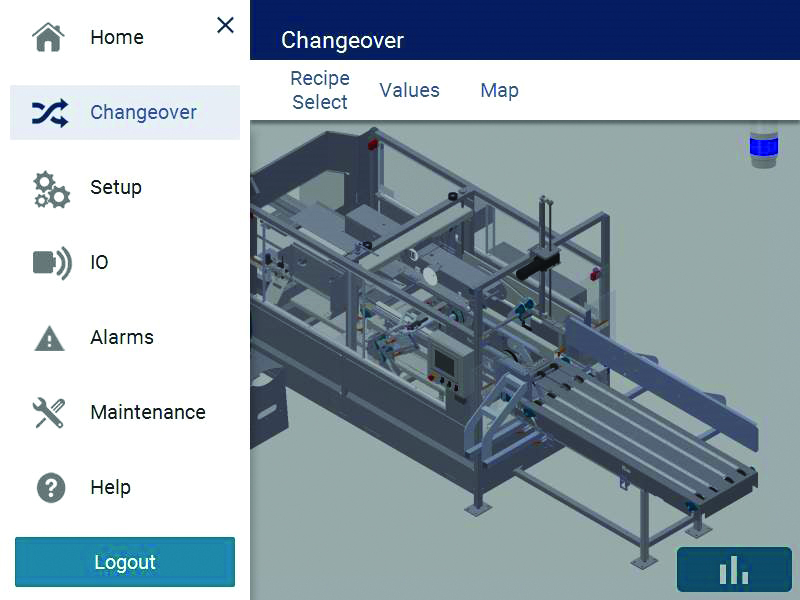

User Centric Design

Help Your Operators Perform

Machine operators that perform their tasks independently free up your maintenance time and keep lines running smoother. Yet frequent turnover, language barriers, and skill gaps in these positions pose significant challenges to operations teams asked to meet production goals while reducing costs in the process.

Every machine in your line is different, and learning the ins and outs of each and every one of them takes time and technical skill – neither of which is freely available at most plants. To offset that burden and still ensure that machines run smoothly, we've dedicated considerable energy into optimizing the human-machine interface.

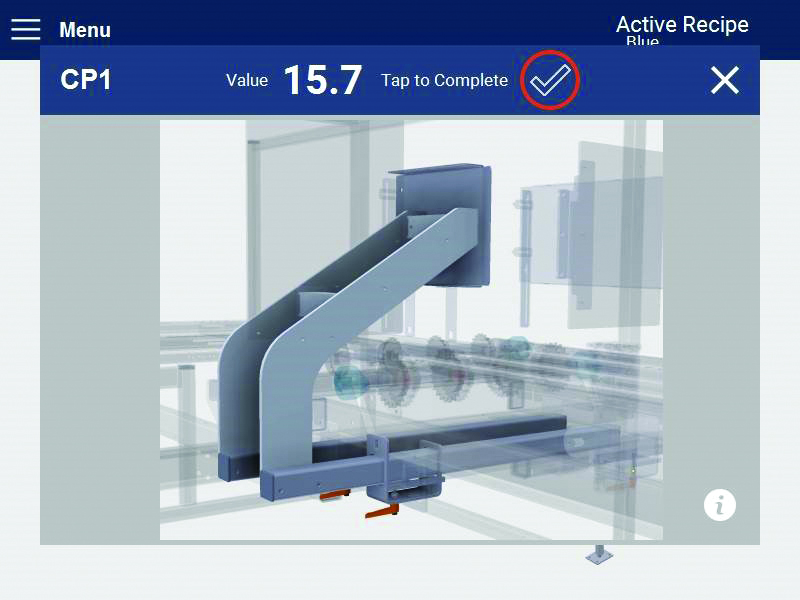

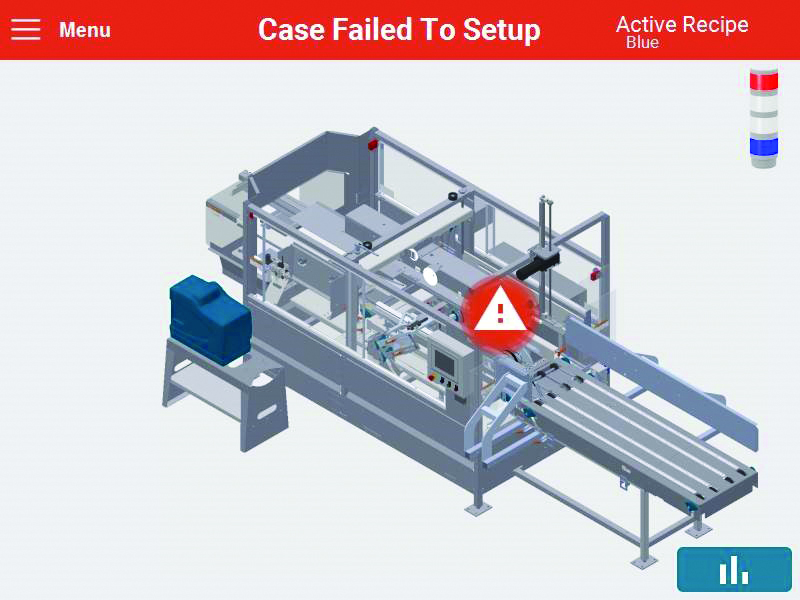

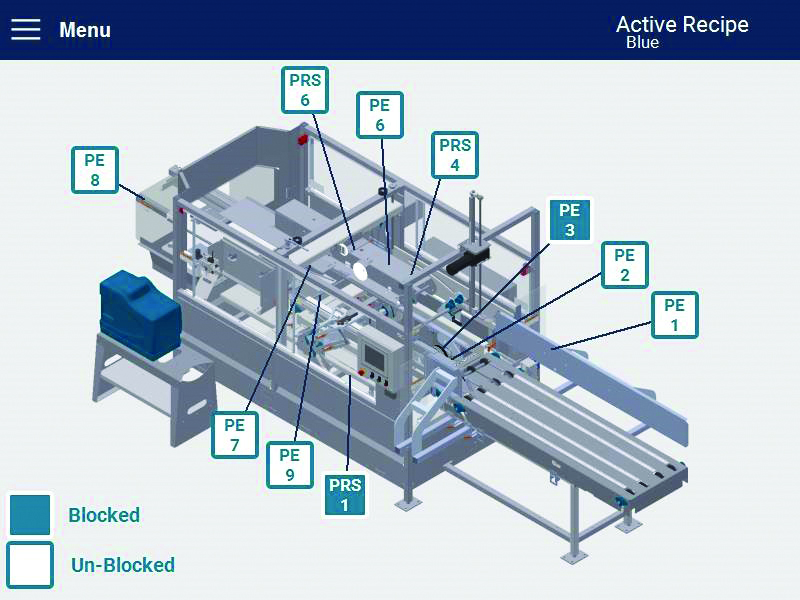

With an uncluttered design, intuitive navigation, interactive guides, live sensor maps and advanced maintenance features, the HMI has morphed into a personal assistant.

- Minimize operator and technician training time

- Increase changeover and fault-recovery speed

- Promote improved machine maintenance and extend equipment life

Check out the videos of our User-Centric HMI (below), standard on all machines with HMI.

Pearson Partner Philosophy

Robust, reliable machines are the foundation of a high performing line. For over six decades, Pearson has built a name for itself. From box formers to packers, closers and palletizers, trust the experience of a long-term automation expert and explore modern features to support reliability, ease-of-use and fast changeover processes.