Modular Solutions

See Which Case Packer Is Right For Your Operation

Explore our Standard Robotic Case Packer portfolio at a glance to find the machine that is most suitable for your application.

- Horizontal Case Packer: Our RTL-HZ packs flexible products horizontally at rates of 65, 110 or 160 products per minute, using one, two, or three delta robots.

- Horizontal/Vertical Case Packer: Our RTL-HV packs flexible products horizontally at rates up to 110 products per minute, and vertically at rates of 10 or 18 cases per minute, using a combination of one, two or three delta robots and one or two catcher robots.

Standard Case Packer

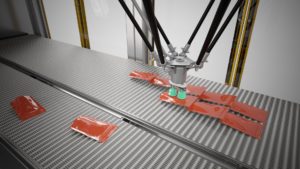

Pearson’s line of RTL-HZ and RTL-HV machines are standardized, modular case packers, capable of loading in horizontal, or horizontal and vertical orientations at a range of speeds. The equipment is optimized to meet the needs of manufacturers who produce lightweight products in flexible packaging formats, such as bags, pouches or flow-wrapped products.

Benefits and Limitations of Standardization

All case packing solutions utilize time-tested techniques and concepts appropriately selected to fit the particular product application. As such, no case packing solution is completely custom. On the other end, no case packing solution will ever be so standardized that it can be considered an off-the-shelf product. However, the further down we go on the continuum of standardization, the larger the benefits become in terms of cost efficiencies and shorter lead times – both critical considerations for most manufacturers.

On the other hand, standardization also narrows the scope of suitable applications to guarantee reliable operation. To strike a good balance and provide a flexible and reliable solution, the RTL-HZ and RTL-HV focus on applications with lightweight (2lbs and under), flexible products. Whether they are bags of frozen vegetables, flow-wrapped facial wipes or pouches of baby food, a single case packer is able to address both horizontal and vertical pack patterns to address the needs of traditional retail outlets as well as shelf-ready requirements.

Modular Solutions for Horizontal or Horizontal and Vertical Case Packing

Pearson’s standard robotic case packers are designed using a delta-style FANUC DR-3iB/8L robot to either pick and pack products flat into a case, or to form patterns in preparation for vertical loading, which is executed by a FANUC M-710iC/50 articulated arm robot. Resembling a catcher’s mitt, this robot collects a full product pattern before the end-of-arm tool clamps down to secure the load as it is being placed into the case.

The delta-robot module is suited for packing exclusively in a horizontal fashion. If products are ever packaged in upright position for shelf-ready applications, or if a manufacturer requires the flexibility to pack both horizontally and vertically, the delta-style and articulated-arm robot modules are linked together. While the base model is capable of loading 65 products/min (PPM) horizontally and 10 cases/min (CPM) vertically, adding further deltas and/or catchers can increase the speed up to 165 PPM horizontally and 18 CPM vertically.

Vision and line tracking facilitate continuous motion within the delta unit, maximizing performance and reducing mechanical wear, while also enabling products to be presented in random orientation, eliminating the need for extensive product conditioning solutions.

And, Pearson’s HMI (Human-Machine-Interface) is intuitive for new users, providing fault alerts and resolution instructions, changeover maps and step-by-step guides, plus the ability to quickly make recipe adjustments.

Additionally, the RTL-HZ and RTL-HV family comes standard with advanced features including remote access, high-visibility machine status lighting, non-contact interlocks, CAT-3 Safety Circuits, an easily accessible grace port, and auxiliary operator station included in the base price.

Get a Quote for a Standard Case Packer Today

Interested in increasing the efficiency of your manufacturing operation? If you’d like to explore if one of Pearson’s standard case packers satisfies your needs, request a quote today. Contact us if you have questions or would like more information any of our standard case packing models.

A good product from the right partner

- Expect a rugged machine design optimized for durability and long equipment life in a 24/7 environment

- Benefit from a uniform user interface for your erecting, packing, sealing, and palletizing equipment

- Count on comprehensive sales, aftermarket, and service support

- Experience premier industry lead-times for faster delivery and shorter down-payment cycles

- Optimally support a high-turnover labor force with the most advanced Human Machine Interface (HMI) in the secondary packaging industry

- Rely on extensively trained and FANUC Certified technicians to service your equipment including FANUC robots

- Have confidence in reliable, thought-out solutions based on 60 years of erecting, packing and sealing and 30 years of robotic integration experience

- Depend on our team of project managers to provide ongoing visibility to meet delivery timelines and budgets

- Always lean on us for 24/7 live service support