Automatic Depalletizing for Mixed Case Stacks

- Application: Automatically unload pallets of mixed cases

- Speed: 5-6 cases per minute

- ROI Justification: Replacing labor and reducing ergonomic injuries on a fully-manual portion of the customer’s line

- Unique Challenges: Vision system lighting interferences (case contrast & discoloration)

- Important to Customer: Completing daily volume of 6,500 cases per day with the ability to grow

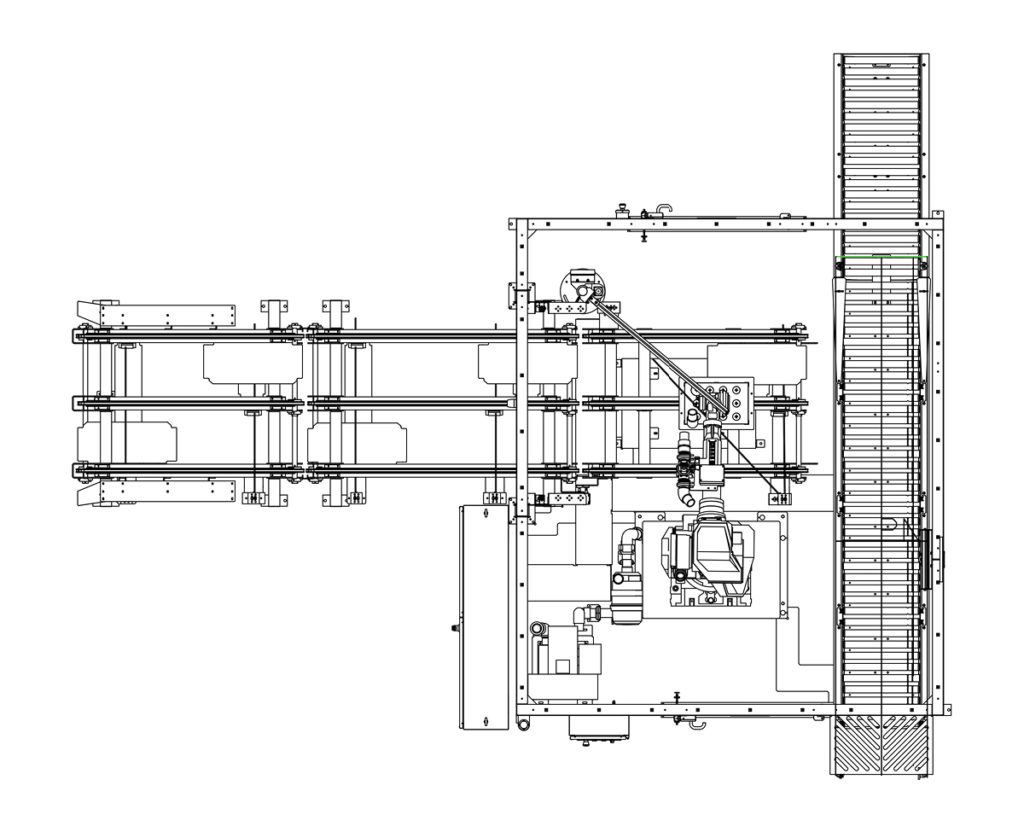

Solved with Pearson’s RDPC-MX Robotic Depalletizer (Over/Under Pallet Position)

A pallet carrying a mixed case load is placed onto a drag conveyor and enters into the cell. A light array protects the vision AI system and limits interference from overhead lighting in order to accurately analyze the pallet load. The system sends depalletizing commands to the robot for each pickable case. In the instance a case is not recognized, a remote call is automatically initiated by the system and a third-party remote monitor provides pick guidance to the robot within seconds.

A pallet carrying a mixed case load is placed onto a drag conveyor and enters into the cell. A light array protects the vision AI system and limits interference from overhead lighting in order to accurately analyze the pallet load. The system sends depalletizing commands to the robot for each pickable case. In the instance a case is not recognized, a remote call is automatically initiated by the system and a third-party remote monitor provides pick guidance to the robot within seconds.

Cases are picked one at a time using a vacuum end-of-arm tool, then placed at the orientation inspection station, where labels are scanned. Correctly-oriented cases are transported downstream to the takeaway conveyor, while non-identifiable cases are ejected from the system for manual reintroduction.

When the pallet load has been depleted, the pallet station lowers to the exit conveyor and advances under the full pallets to exit the cell. The empty conveyor raises up and receive the next pallet. The system is capable of handling up to 10,000 cases daily, easily allowing for production volume increases over time.

RDPC Specs

- Application: Configurable Robotic Depalletizer

- Capabilities: Mixed pallet handling with optional layer-by-layer picking, item classification, empty pallet detection, place verification, offset picking

- Supported Items: Boxes, overwrapped trays, cartons, bags

- Speed: Up to 10 cases per minute depending on application

- Controls: FANUC PMC | AB CompactLogix PLC I PanelView Color HMI

- Operation: Robotically using multi-axis articulated robot with MTBF of over 80,000

- Programming Language: PackML

- Safety Guarding: Fencing, light curtains, area sensors

Minimized Total Cost of Ownership

- Robotic Operation takes advantage of high mean between failure of 80,000 hrs, reduced parts count and wear

- Standard remote access capability for efficient technical support and extensive service cost savings

- HMI models web experience for quick familiarity, intuitive operation, reduced training needs and better upkeep of the equipment

- Tune-Up Plus Program ensures optimal uptime and controlled parts and service expenses year over year

Interested to learn more about this solution?

Click here to contact us today!