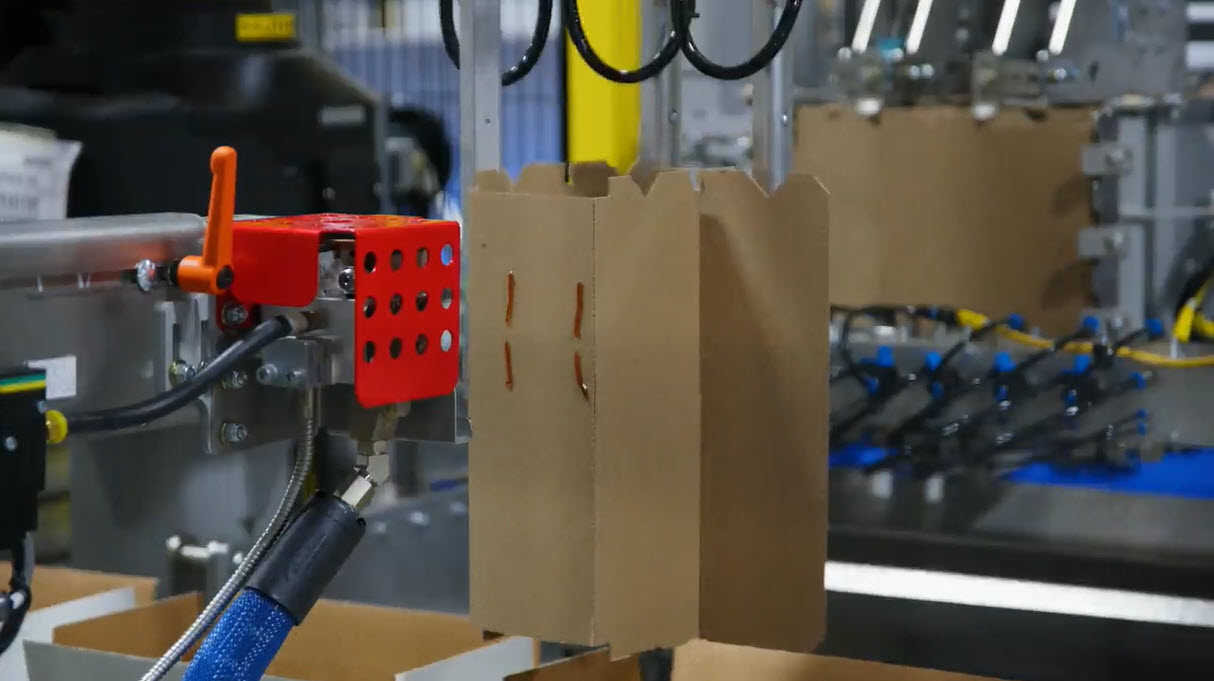

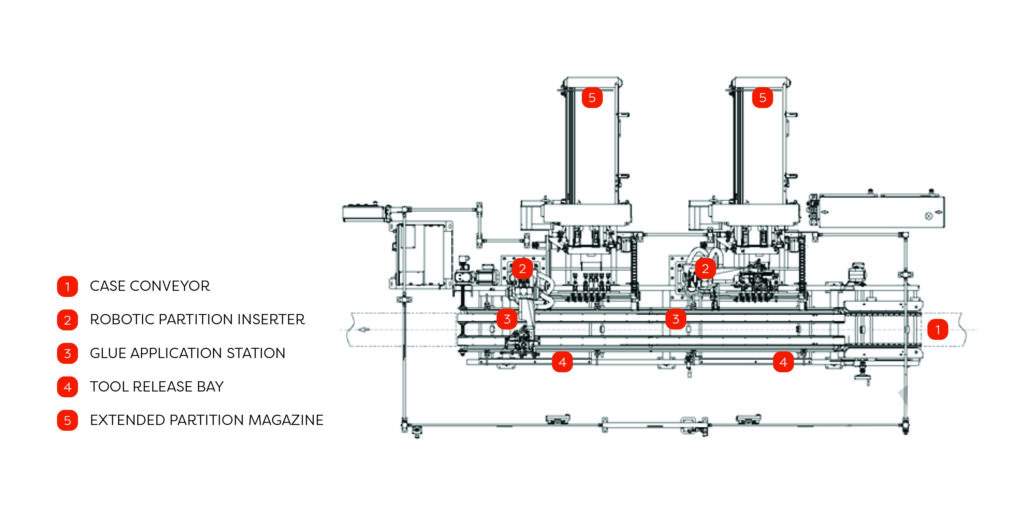

This southeastern US winery needed a robotic partition inserting solution for a new facility they were building. With installed Pearson case erectors and sealers at sister facilities, confidence in machine performance and OEM support was already established.

The mechanical partition inserters operating in their existing facilities were not optimal for running multiple partition styles and cases on the same line, as the changeover process was cumbersome and hugely time-consuming (as much as 30 minutes!). For this

project, three different partition styles would need to run on a single machine, with the expectation that more partition styles would be added in the future. And, one partition style would need to be glued to the inside of it’s cases.

On account of rising labor costs and shortages, the ideal solution would require minimal manual resources to oversee operation and restock consumables.