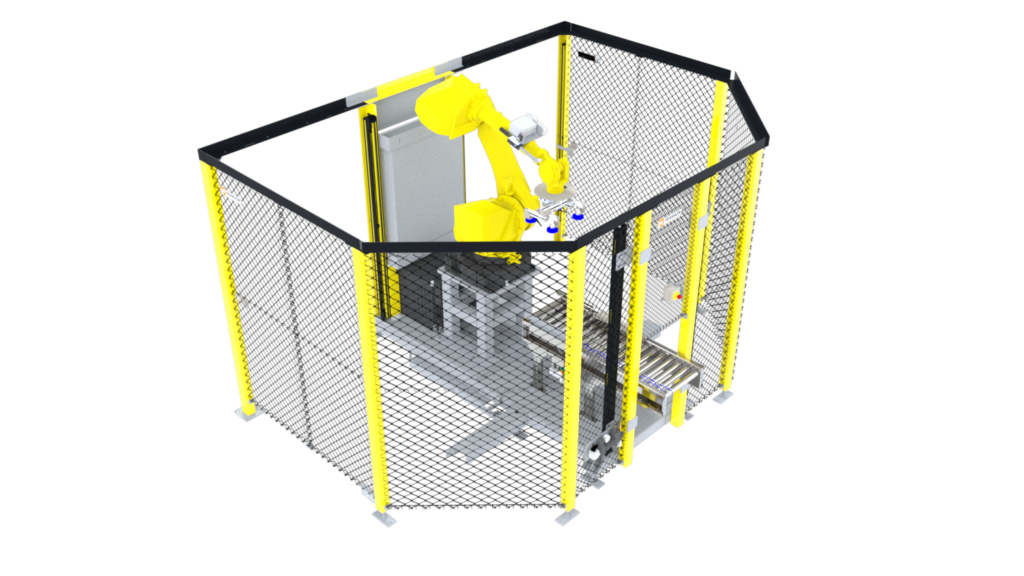

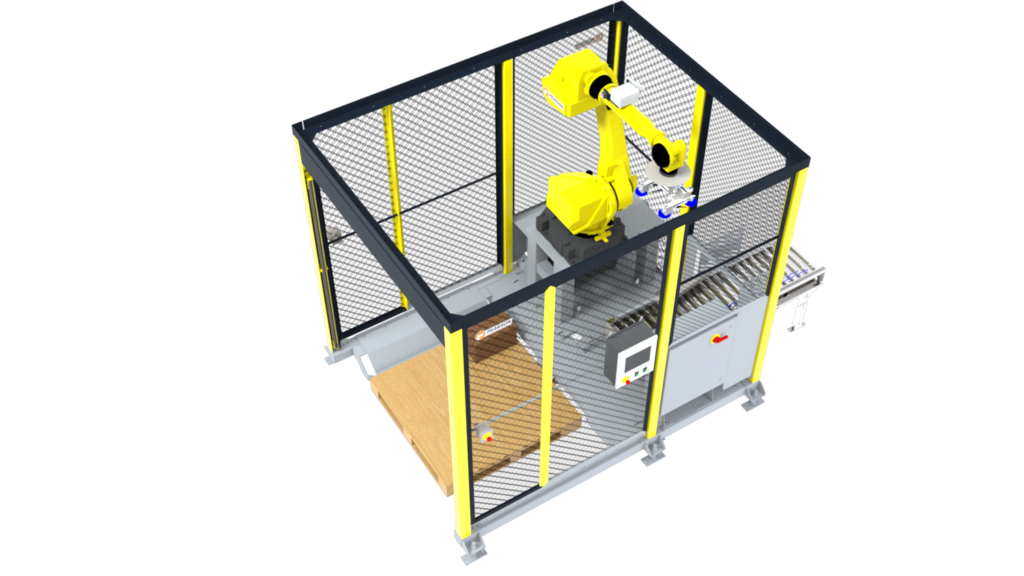

Robotic Palletizer/Depalletizer

CPC-C Compact Cobot Palletizer

Specifications

-

Products

-

Bags

-

Bottles

-

Jars

-

Jugs

-

Pails

-

RSC Cases

-

-

Speed

Up to 8 cycles per minute, single or multi-pick

*depending on pattern type, case orientation & case weight.

- Product Weight Up to 35 lbs

- Infeed Motorized roller conveyor with embedded case reference

- Pallet Height Up to 72 inches

-

Pallet Handling

- Manual

-

Min. Case Size

- 9" (L) x 5" (W) x 6" (H)

-

Max. Case Size

- 17.5" (L) x 15" (W) x 20" (H)

- Operation Collaborative Robotic

-

Changeover

Easy-to-use pallet configuration tool to create, modify, copy or clear new pattern recipes on the HMI.

-

Construction

- Low Pressure Washdown

- Mild Steel

-

Machine Size Range (ft)

- 10.5 (L) x 8 (W) x 8 (H)

-

Controls

- Allen-Bradley OptixPanel 2800 Color HMI

- Allen-Bradley PLC

- PackML Compliant

- Guarding With or without barrier guarding or safety scanners

- Air Requirements 80 PSI at 5 SCFM

- Power Requirements 110 VAC

- Disconnect Sizes 20 Amps

User Centric Design

User centric design is about making the interaction with our machines as intuitive as possible. We want to reduce the learning curve for operators and maintenance technicians, make it easy to interpret data from the machine into actionable information, minimize the margin for human errors and make set up, changeover and fault recovery a faster and more seamless process resulting in improved up time and equipment availability.