Configurable Solutions

Case Packer

Has your search for increased efficiency for your packing operation led you to us? If you are looking to automate your manual loading process, expand your packaging operation or replace inefficient and outdated packers, you have come to the right place. Pearson Packaging Systems is eager to support you with robotic top-load solutions to fit your specific requirements.

Since pack applications differ widely from one customer to another depending on the type of product, it's unique properties, rate of speed, pack patterns, space constraints and many more factors, a one-size-fits-all solution would not deliver the results you are looking for.

In Pearson Packaging Systems you find a reliable partner with over 65 years of experience in building packaging equipment and over 30 years of integrating robots to provide fully automated systems that streamline your packing operations and achieve maximum performance with minimal downtime. Whether you need a quote or want to explore options for your end-of-line operation, fill out a contact form, and discover what Pearson has to offer.

Robotic Technology for Reliability and Flexibility

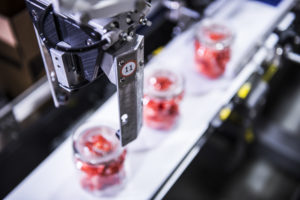

Due to their reliability, flexibility and precision, robotics have received enormous attention in the packaging industry. And rightfully so. Over the past decade, cost for robots have come down significantly making them not only a viable alternative to traditional mechanical packers but often the preferred choice. Enhanced with advanced technologies including vision guidance and line tracking to inspect, detect, sort and manipulate products on the fly or balance the load between robots, application-specific end-of-arm tools and automatic changeover, Pearson’s case packers effectively support your desire for optimal efficiency in your packaging operation.

Robotic Top Load Case Packers Optimized to Your Specific Needs

Individual products and facilities come with their own sets of specifications and challenges. We work with our customers to provide sustainable, long-lasting solutions for their unique businesses and specific applications. We have extensive experience using various types of robots, employing a wide variety of product handling, transfer and loading techniques, meeting stringent environmental requirements, and integrating numerous product conveying technologies and third party OEM equipment. This enables us to select the best options for your particular needs and provide a comprehensive automated solution.

In addition to our long-term experience building and deploying automatic packing solutions, we employ various simulation and visualization tools to account for potential variables and validate concepts.

Cut Costs With Automated Case Packers

Automatic case packers, just like any form of automation, reduce your labor cost including wages, recruitment, training and possible injuries, and increase your throughput rate and quality output.

The use of robotics in our top loaders offers the additional benefit of high reliability and uptime with a Meantime Between Failure (MBF) ranging between 80,000-120,000 hrs as reported by FANUC Robotics. Robots are also highly flexible in that they can easily accommodate multiple products, sizes or pack patterns without changeover or if necessary automatic changeover. Robotic arms can offer articulation that mimics the motion of hand movements gently maneuvering a product into a case. In addition, robots are easily redeployable if your packing requirements change.

Pearson further optimizes its packaging machines with the industry’s most advanced human-machine interface (HMI) that replicates a website experience and thus helps operators and technicians to intuitively learn the machine and independently troubleshoot when necessary. This reduces your training cost and positively affects uptime. All of our robotic top loaders are also equipped with remote access capability to enable fast and efficient service support without the cost of in-person visits.

Get a Quote for Case Packer Machines Today

If you need a robotic case packer for your product, allow us to design a solution. Feel free to fill out our online contact form or request a product quote now for additional details.

What are you packing?

- Packaged fresh or frozen food

- Flexible bags or irregular shaped products

- Retail-ready stand-up pouches

- Flow-wrapped packages or bags

- Packets or sachets

- Single-serving cups or tubs

- Filled bottles and jugs

- Chipboard cartons

Into what?

- RSC or HSC corrugated cases

- Chipboard cartons

- Bliss boxes or Trays

- Distribution and warehouse totes

Yes? Then Let's Talk!

In the world of case packing, you have two main container options – putting your product into pre-built cases such as RSC, HSC, Bliss or Tray boxes that come as knockdowns with a manufacturer’s seam from your corrugate supplier or a corrugated blank sheet that is formed around your product, also called a wraparound.

Pearson Case Packers are optimized solutions for packaged products that go into pre-built, top-loaded containers.

With such focus comes concentrated experience with thousands of such case packing projects under our belt and deep expertise around overcoming the challenges of creating suitable pack patterns of often randomly oriented products, reliably picking the frequently challenging flexible or slick materials and uniquely shaped forms and placing those products at the expected rate, without damage to either case or product. Advancing from the earlier years of mechanical, gantry-style top-loading, Pearson is now also fully committed to the myriad of benefits robots provide and exclusively offers robotic packing solutions.

Work with the expert in top-load, robotic case packing!

Work with the expert in robotic top loading!

The following list of capabilities provides insight into the skills and tools we can recruit to overcome even the most unique picking and packing challenges.

- Product handling and transfer to include sorting, orienting, and collating

- Grouping of products to form pack patterns including vertical and/or horizontal loading techniques, interleaved, stacked, on edge, on end, rainbow or variety packs, bulk and shelf-ready

- Various product conveying technologies including servo collator, diverting, tabletop, mat top and independent cart technology to meet the requirements of the application (type of product, speed, pack configurations, material handling considerations)

- Ability to meet stringent requirements of washdown, freezing, dusty, hot, or humid environments

- Experience with articulated arm, delta and Scara robots to select best fit for the application based on capability (reach and payload), flexibility and price

- Vision guidance and line tracking to inspect, detect, sort and manipulate products on the fly or balance the load between robots

- Application specific end-of-arm tool and/or automatic tool changeover

- Robotic simulation for concept testing and visualization

- Human Machine Interface supported by our proprietary User Centric Design to enable operators and maintainers to quickly learn and efficiently use the equipment

A good product from the right partner

- Expect a rugged machine design optimized for durability and long equipment life in a 24/7 environment

- Benefit from a uniform user interface for your erecting, packing, sealing, and palletizing equipment

- Count on comprehensive sales, aftermarket, and service support

- Experience premier industry lead-times for faster delivery and shorter down-payment cycles

- Optimally support a high-turnover labor force with the most advanced Human Machine Interface (HMI) in the secondary packaging industry

- Rely on extensively trained and FANUC Certified technicians to service your equipment including FANUC robots

- Have confidence in reliable, thought-out solutions based on 60 years of erecting, packing and sealing and 30 years of robotic integration experience

- Depend on our team of project managers to provide ongoing visibility to meet delivery timelines and budgets

- Always lean on us for 24/7 live service support

- If CapEx is unavailable, but automation should not be delayed, talk to us about our Machine-as-a-Service program