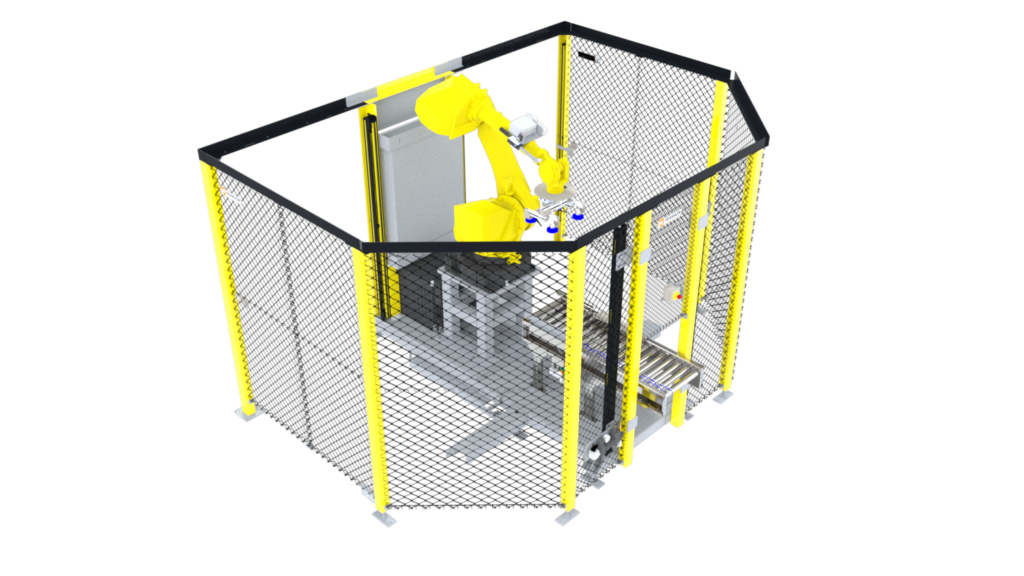

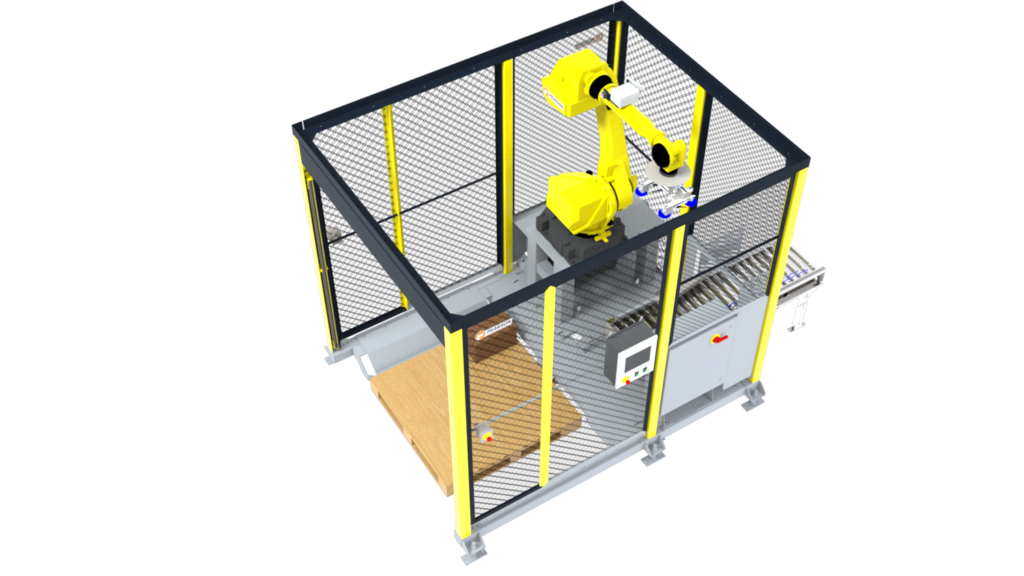

CE15 Case Erector

Specifications

-

Speed

- Up to 15 cases/min

-

Min. Case Size

- 8" (L) x 5.5" (W) x 3" (H)

-

Max. Case Size

- 20" (L) x 14" (W) x 14" (H)

-

Sealing

- Tape

- Operation Pneumatic

-

Changeover

Manual with HMI graphical guided instructions, changeover map, scales, pointers, and quick release handles

5 min (estimate for trained technician) -

Construction

- Mild Steel

-

Machine Size Range (ft)

- 11 (L) x 5 (W) x 6 (H)

-

Controls

- Allen-Bradley CompactLogix PLC

- Allen-Bradley OptixPanel 2800 Color HMI

- PackML Compliant

- Air Requirements 80 PSI

- Power Requirements 460 VAC 3 Phase

- Disconnect Sizes 30 Amps

-

Air Consumption

1.3 SCF/Cycle

-

FLA (Full Load Amp) of Base Machine

10 Amps

-

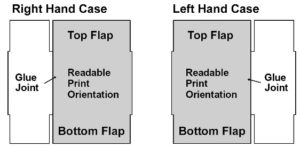

Case Support

-

CSSC

-

HSC

-

RSC

-

User Centric Design

User centric design is about making the interaction with our machines as intuitive as possible. We want to reduce the learning curve for operators and maintenance technicians, make it easy to interpret data from the machine into actionable information, minimize the margin for human errors and make set up, changeover and fault recovery a faster and more seamless process resulting in improved up time and equipment availability.

Popular Upgrade Options

Additional Tape Head

A spare tape head allows quicker replacement of tape by exchanging the entire head and refilling the empty one while the machine is back up and running.

Auxiliary Operations Station

An auxiliary operator station enables easy access to cycle start/stop, reset, and emergency stop pushbutton functions on both sides of the machine.

Extended Magazine

Case erector magazine extensions allow longer continuous machine operation between magazine reloads. A variety of horizontal and vertical magazine extension upgrades are available and range from 2 feet to more than 16 feet depending on the machine and available floor space.

LED 4-Light Beacon w/ Horn

LED 4-Light Beacon w/ Horn

Low or High Temperature Package

Electrical enclosures located in cold and humid environments maintain better performance and longevity with the addition of a heater and drier package. In high-temperature environments, the addition of an air conditioner may be necessary for optimal performance.

Remote Access Router

A remote access router mounted in the electrical cabinet allows secure Internet VPN connection to a machine or system for support and control program change needs. This capability is included with every Pearson engineered system and as an option on all individual machines. Remote service access offers the potential to reduce on-site service trips. Internet connectivity is available via direct Ethernet, Wi-Fi, or cellular methods.

Tape Sensing

Sensors detect fail-to apply, fail-to-cut and low tape situation.

Videos

- Hot Melt Adhesive and Industrial Machine Tapes

- Wide Range of OEM Verified Formulas

- Competitive Pricing

- Extended 1-Year Warranty for Your Pearson Equipment