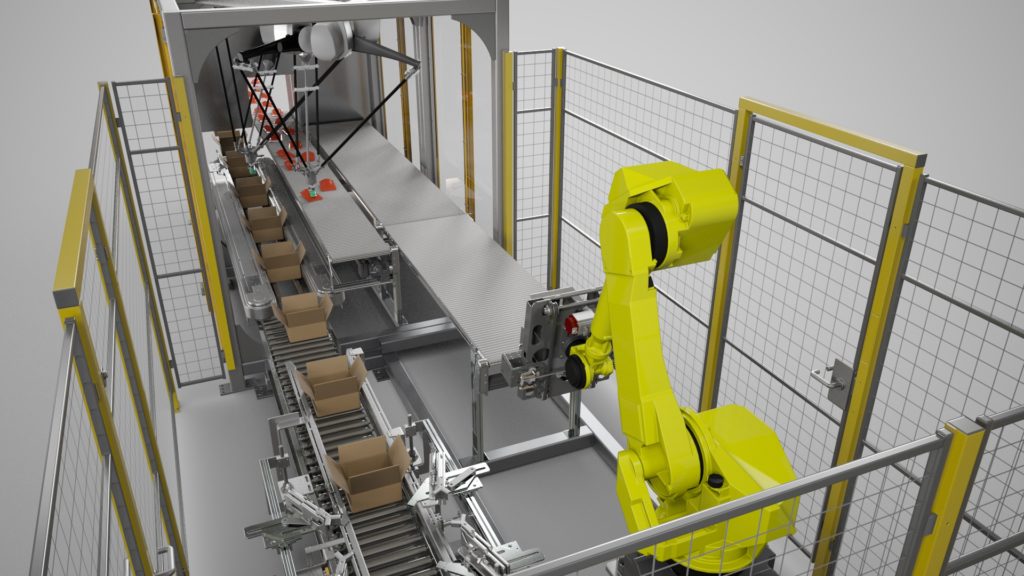

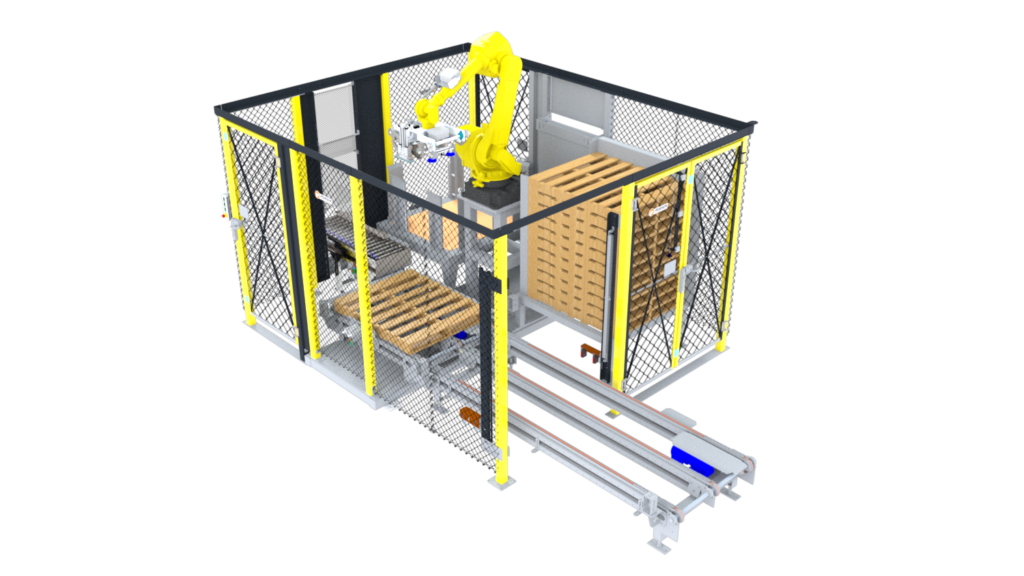

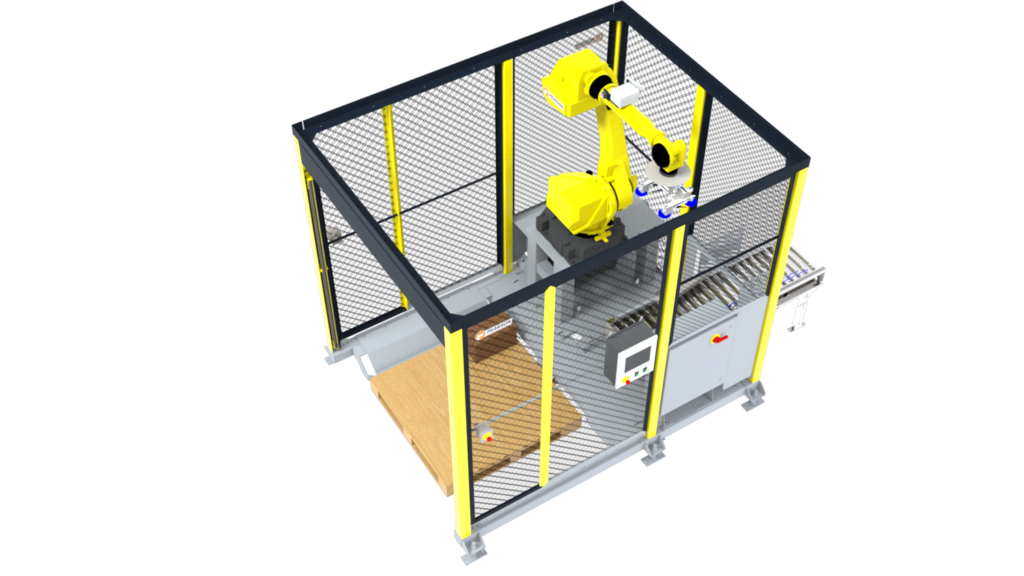

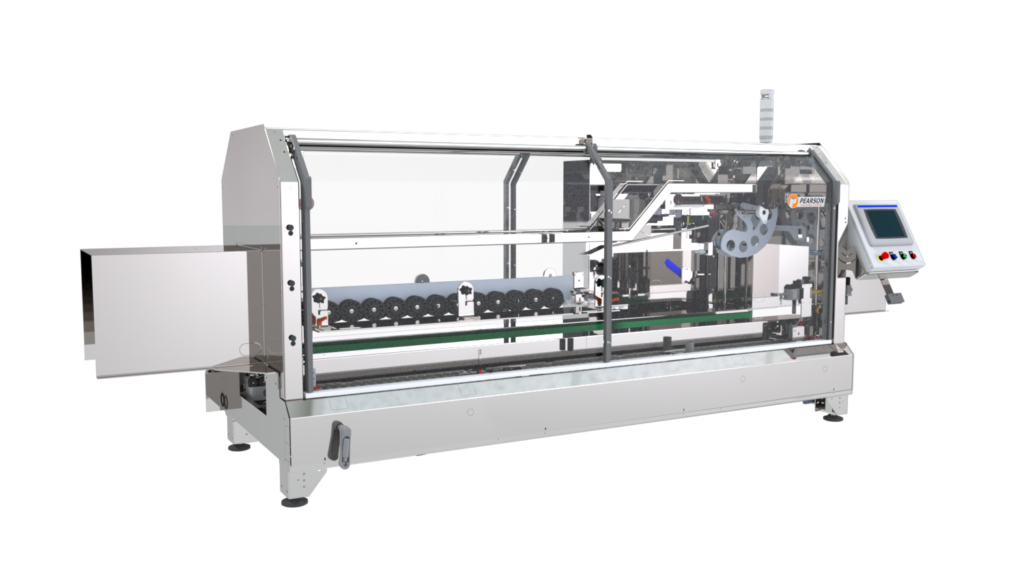

RTL-HZ Horizontal Case Packer

Specifications

-

Speed

Up to 65/110/160 products per minute

- Rates vary depending on number of robots.

-

Min. Case Size

- 9" (L) x 4.5" (W) x 6" (H)

- Products weighing up to 2lbs

-

Max. Case Size

- 24" (L) x 14" (W) x 15" (H)

- Products weighing up to 2lbs

- Operation Robotic

-

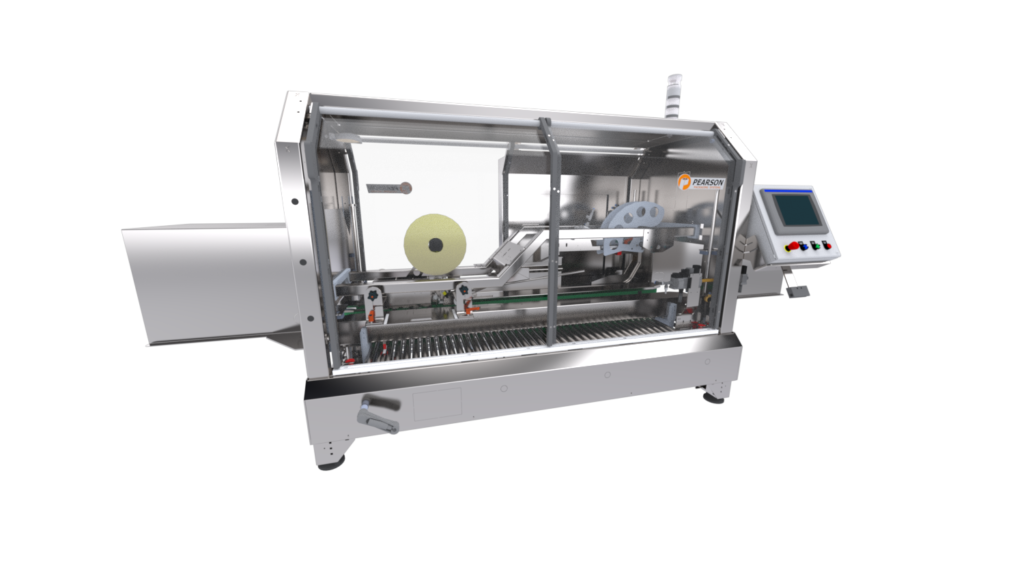

Changeover

• HMI graphical guided instructions

• Fast – tool-free changeover and externally accessible adjustments

• 5 min (estimate for trained technician) -

Construction

- Mild Steel

- Stainless Steel

-

Machine Size Range (ft)

- 10.3-22.3 (L) x 7.5 (W) x (H)

-

Controls

- Allen-Bradley CompactLogix PLC

- Allen-Bradley OptixPanel 2800 Color HMI

- Fanuc Robot Controller

- PackML Compliant

- Air Requirements 80 PSI

- Power Requirements 460V / 3Ph / 60Hz

-

Case Support

-

Bliss Display

-

Bliss Shipper

-

CSSC

-

FOL

-

HSC

-

RSC

-

Standard Tray

-

Ultra-small Case Sizes

-

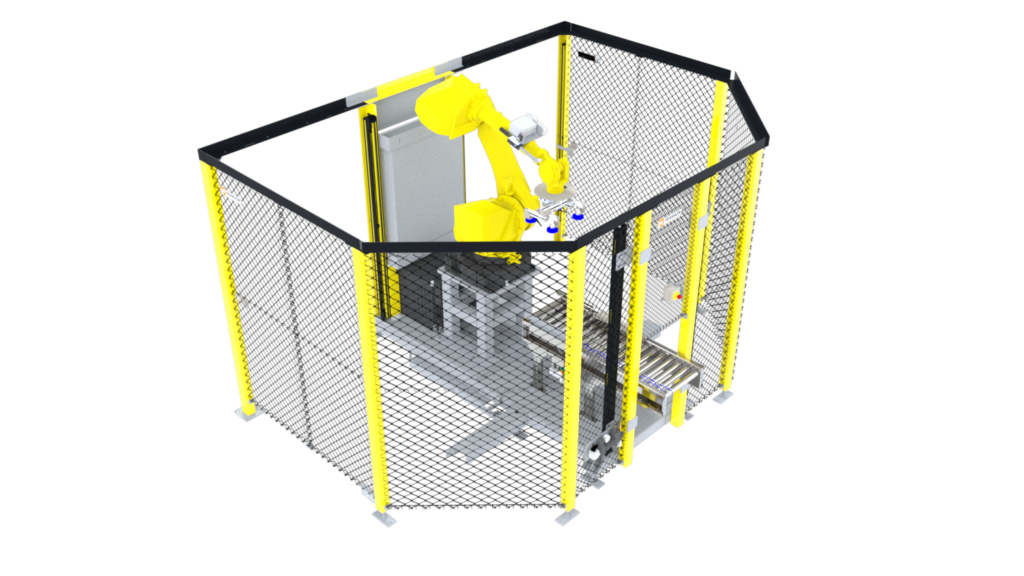

User Centric Design

User centric design is about making the interaction with our machines as intuitive as possible. We want to reduce the learning curve for operators and maintenance technicians, make it easy to interpret data from the machine into actionable information, minimize the margin for human errors and make set up, changeover and fault recovery a faster and more seamless process resulting in improved up time and equipment availability.

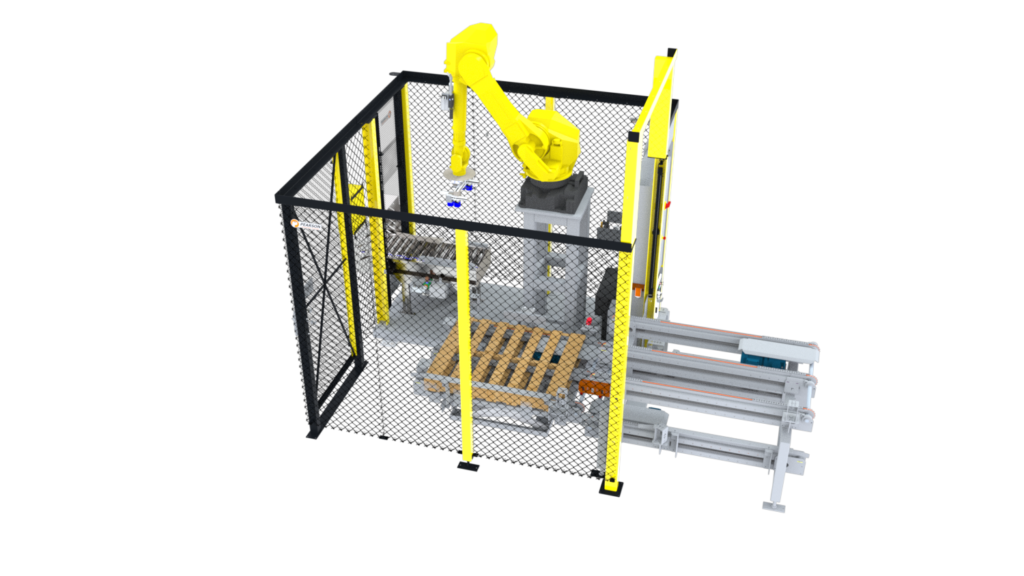

Popular Upgrade Options

Air-Conditioner

Air conditioning provides cooling when ambient temperature becomes too hot or the contents of the electrical enclosure generate heat that risk failure to components.

Low or High Temperature Package

Electrical enclosures located in cold and humid environments maintain better performance and longevity with the addition of a heater and drier package. In high-temperature environments, the addition of an air conditioner may be necessary for optimal performance.

Videos

Downloads

Not Just a Good Product but a Reliable Partner

- Rugged machine design optimized for durability in a 24/7 environment

- Uniform user interface across the entire product portfolio

- Intuitive Human Machine Interface (HMI) to support a high-turnover labor force

- Reliable, thought-out solutions based on nearly 70 years of experience

- Comprehensive sales, aftermarket, and service support

- Large team of extensively trained technicians to service your equipment

- 24/7 live service support

- Premier industry lead-times for faster delivery and shorter down-payment cycles

- Team of project managers provides ongoing visibility to meet delivery timelines and budgets