A spike in ergonomic injuries and a diminishing workforce prompted this wire and cable manufacturer to seek an automated solution for its existing industrial and retail product lines. Each cell would need to carry out slightly different tasks, but both needed to be highly-flexible in function, fit into a compact footprint, and ensure superior quality control.

Project Overview

Objective 1: Reduce manual labor requirements

Maintaining sufficient staffing on a daily basis was extremely challenging. Undesirable shift schedules and a declining worker skill set made future increases in throughput unachievable.

Additionally, worker injuries from the repetitive motion of erecting cases, packing products, and sealing cases by hand needed to be addressed with a safe, ergonomically-friendly solution.

Pearson Solutions

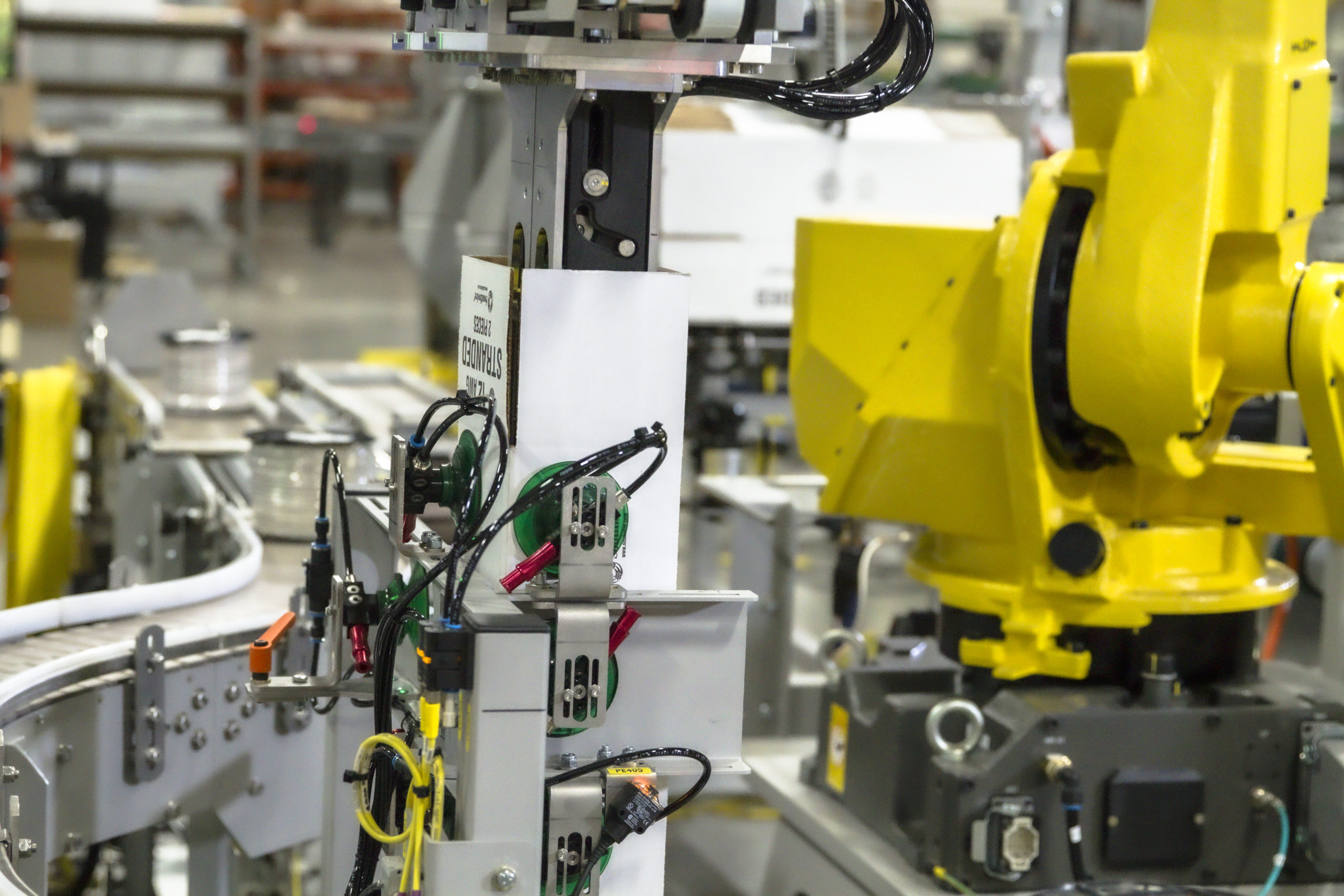

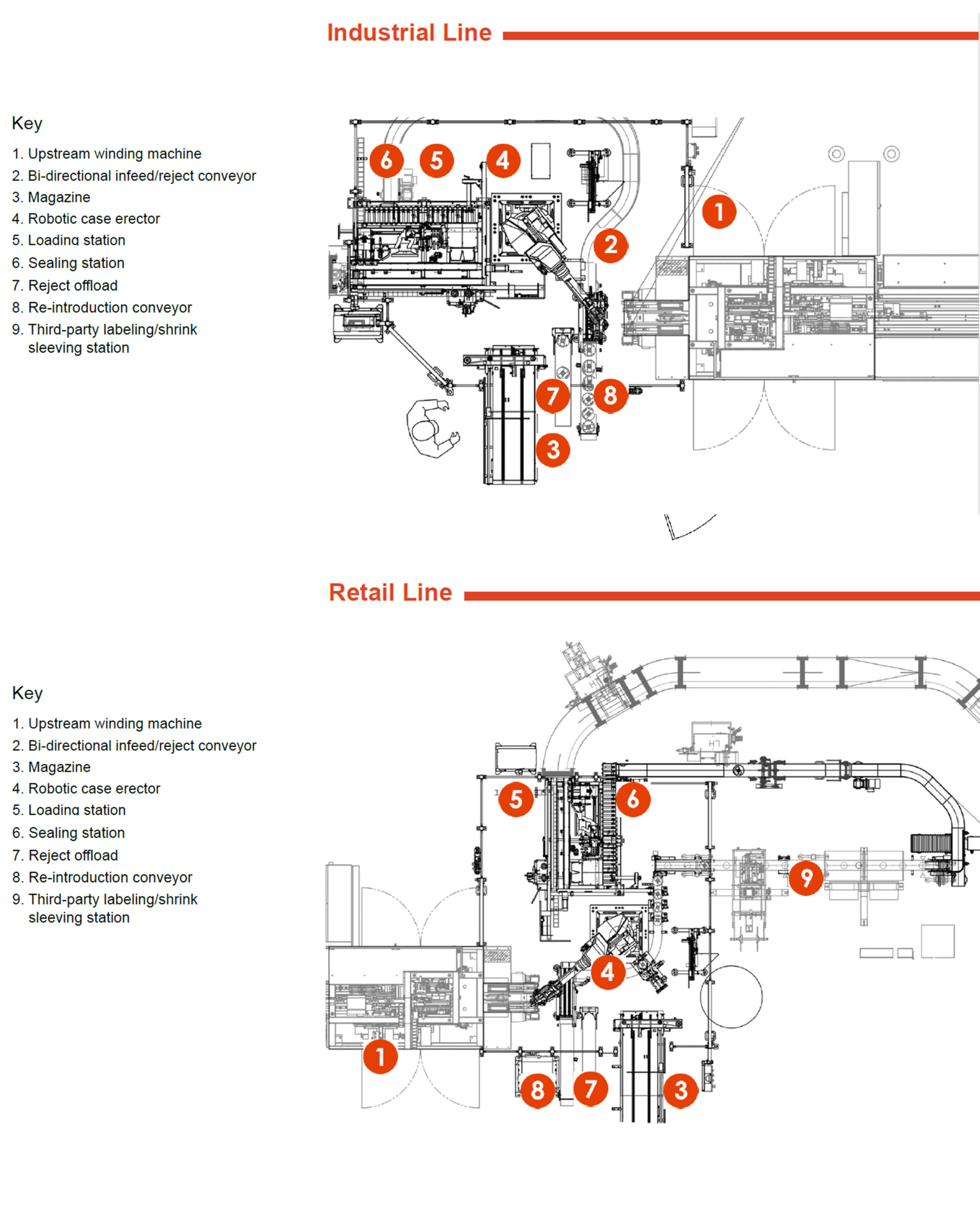

One M-710iC/50 FANUC robot per line replaced all dedicated operators previously required for case erecting, packing and sealing tasks. With the design supplied by Pearson, manual intervention is only necessary to remove and fix rejected spools not meeting the customer’s quality control standards.

Objective 2: Perform multiple functions within a small space

Case erecting, product handling, shrink sleeving, and case sealing functionality would need to fit within the current limited space.

Pearson Solutions

The relatively slow operating rate of eight cases per minute makes it possible for a single robot to perform all necessary erect, pack and seal tasks within its normal reach and without requiring changeovers.

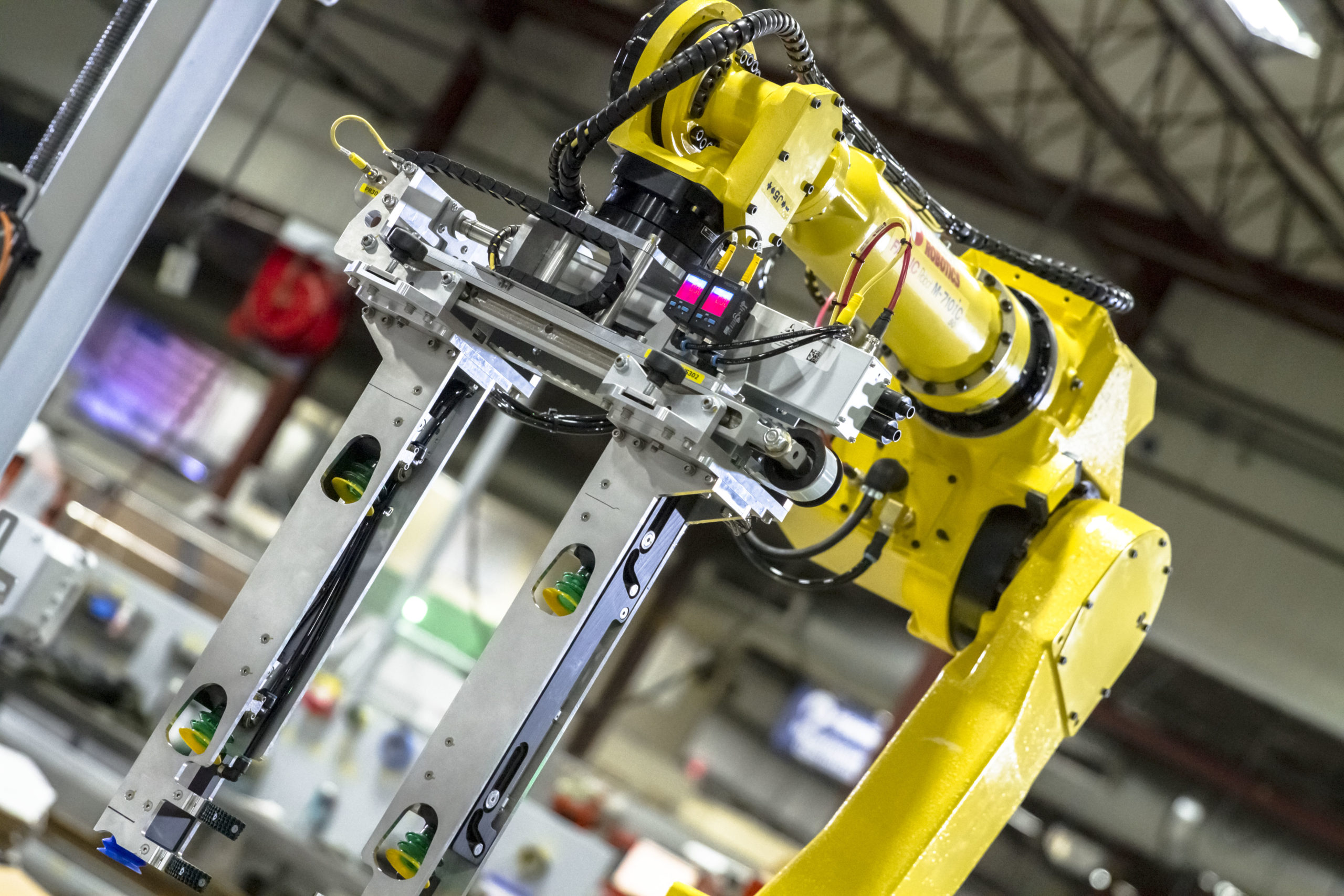

The robotic end-of-arm tools (EOATs) incorporate vacuum cups, as well as grippers, to handle both cases and products. The tools are long and linear in shape to fit into deep cases for top sealing, transport, and bottom sealing. A mechanical push mechanism packs spools into boxes.On the retail line, an existing conveyor and third-party shrink sleever were integrated to prepare products for packing.

Objective 3: Maximize uptime and ensure quality output

It was critical that incomplete, damaged or otherwise inadequate wire spools entering the cell from the upstream winding machine be prevented from being packed into cases for distribution.

Pearson Solutions

Pearson’s design incorporated reject systems equipped to send out alerts when a flawed spool enters from the upstream coiling system. A bi-directional conveyor will transport quality spools to the pack station or reject faulty spools outside the cell for manual intervention. The robots receive a signal when corrected spools are manually reintroduced into the cell and then transport them to the packing station for continued processing following the normal sequence.

Sequence of Operations

On both the industrial and retail lines, a robotic case erector equipped with vacuum cups picks a horizontal case from the powered case magazine using articulated motion. It rotates the case vertically and uses the opposing vacuum plate at the erecting station to secure it before pulling the knockdown open. Once erected, the EOAT is inserted into the case. Minor panel vacuum cups hold the case squarely open as plows fold down the minor flaps.

Next, the robot transports the case to the sealing station and guides the case through the major flap plows and across the glue head, applying compression against a base plate to ensure a proper seal.

On the non-retail line, the upstream winding machine detects flawed spools as they exit and sends a reject notification to the erect, pack, seal cell. A belt transfer sends adequate spools toward the pack station, while faulty spools are transported via a reject conveyor for manual rework outside of the cell. On the retail line, a Pearson-provided

detection system equipped with sensors verifies that plastic sleeves are placed properly around spools before they transfer into the downstream heat shrink equipment. A reject pusher discharges inadequate spools out of the cell when necessary.

Reintroduced spools are retrieved by the robot using an end-of-arm gripping tool and placed back onto the infeed conveyor, resuming normal operation thereafter. The robot releases the case at the loading station where it is rotated onto its side for loading. On the non-retail line, a plunger mechanism pushes one or two spools at a time (depending on pack pattern) into the open case. The full case is indexed to the final sealing station where the two minor flaps and one of the major flaps are closed. As the case transfers past a glue applicator, the second major flap is plowed closed. The sealed case is compressed as it moves through a sidebelt conveyor and exits the cell to continue to a downstream labeler and palletizer.

On the retail line, wire spools are wrapped prior to case packing. The robot EOAT is equipped with a gripper designed to securely grasp around the spool body. It picks spools one at a time from one of two discharge positions and places the spool onto a conveyor for transport to a nearby labeling and/or shrink sleeving station. Once the label/

shrink sleeve application is complete, the spools move to be loaded and sealed the same manner as on the non-retail line.