This Arizona-based company was prepared to invest in a brand new co-packing facility and needed a packing solution dedicated to one customers’ snack pouch products. The snack bags would need to be packed vertically into cases at high rates of speed while maintaining product integrity. Furthermore, the solution would need to fit in a limited footprint.

Project Overview

Objective 1: High speeds within a limited footprint

Pack rates of 180 snack bags per minute would need to be reached to keep up with two upstream bagging machines that the customer had already purchased to meet the necessary output volumes. And, the design of the cell would need to be as compact as possible on account of limited space within the facility.

Pearson Solutions

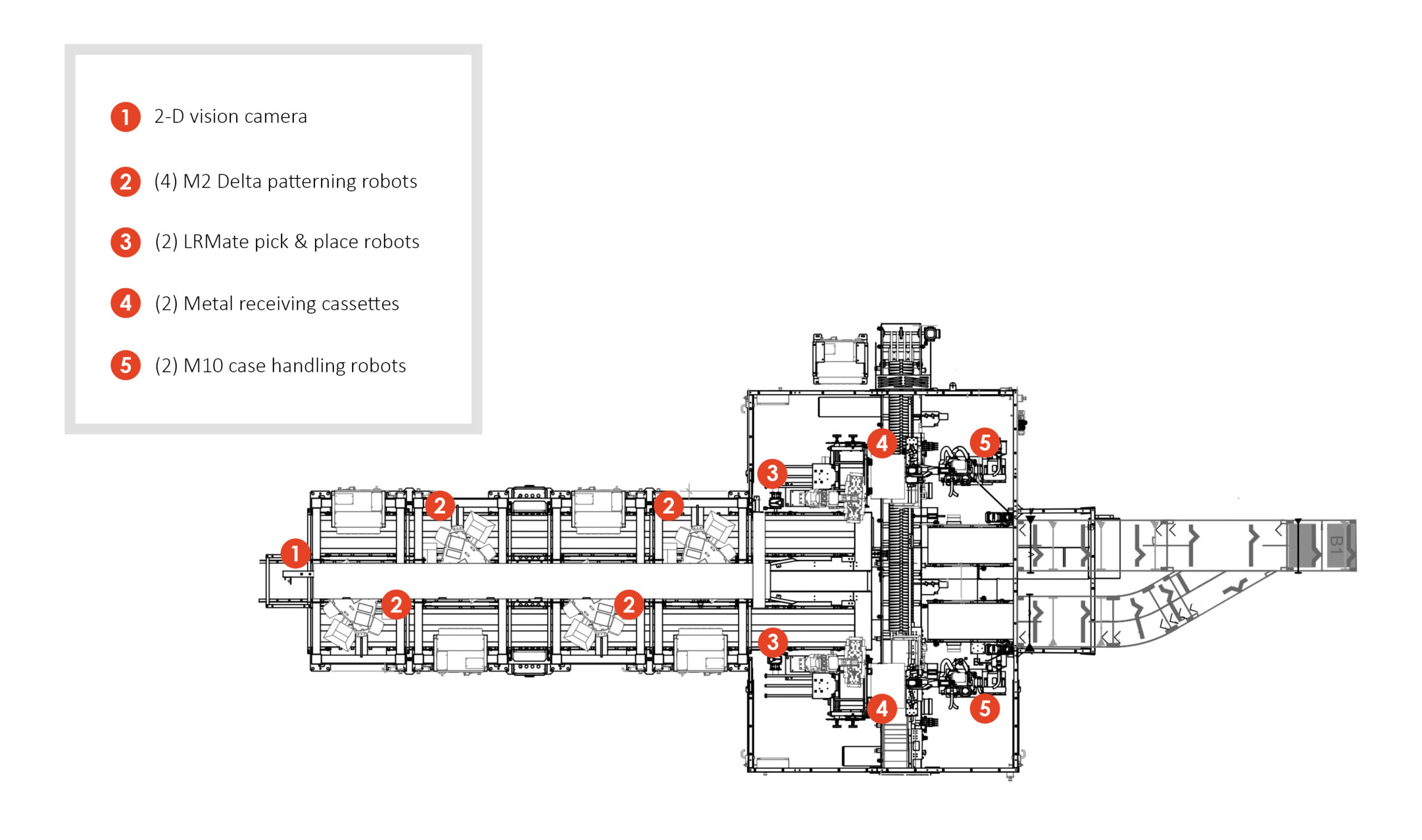

To reach the required rates within a tight footprint, centralized dual lanes are used to transport products through the cell where eight robots share the workload: forming product patterns, preparing empty cases for loading and picking and placing the product into the cases

Objective 2: Consistent vertical packing & maintained product integrity

The snack pouch products would be received in random lay-flat orientation and would need to be rotated on-edge when packed into cases. Delicate handling would be necessary to avoid damaging the

products.

Pearson Solutions

Products are picked one layer at a time by two LRMate robots equipped with vacuum end-of-arm tooling and placed into two metal loading cassettes. When a case pack is complete, a servo pusher gently presses the product stack out through metal back panel flaps and into awaiting cases held on their side by two M10 robots.

Objective 3: Flexibility to handle future production changes

A level of flexibility would need to be built in as the customer anticipated new product mixes and case introductions over the next couple of years, including a dual flavor variety pack they were proactively planning for.

Pearson Solutions

By understanding future requirements upfront, the two-lane design was selected and pre-programming work was done to make future product introductions as seamless as possible.

Sequence of Operations

Products are received face-up in random orientation on two product lines. They transfer onto conveyors to enter the cell where a 1) 2-D vision camera checks for product location and orientation. 2) Four M2 Delta robots pick and place individual bags from the center conveyor and place them onto pattern conveyors based on the case recipe selected.

Empty cases convey into the cell on a table top conveyor where 5) two M10 robots pick up and rotate them on their side in front of 4) dual metal loading cassettes.

3) Two LRMate robots pick products horizontally and place them layer-by-layer into the cassettes. Once a case pack is complete, a servo pusher gently presses the product out through metal back flap panels and into awaiting cases. The 5) M10 robots place the full cases upright onto the takeaway conveyor as the pattern forming, layer picking and placing, and packing sequence continues.