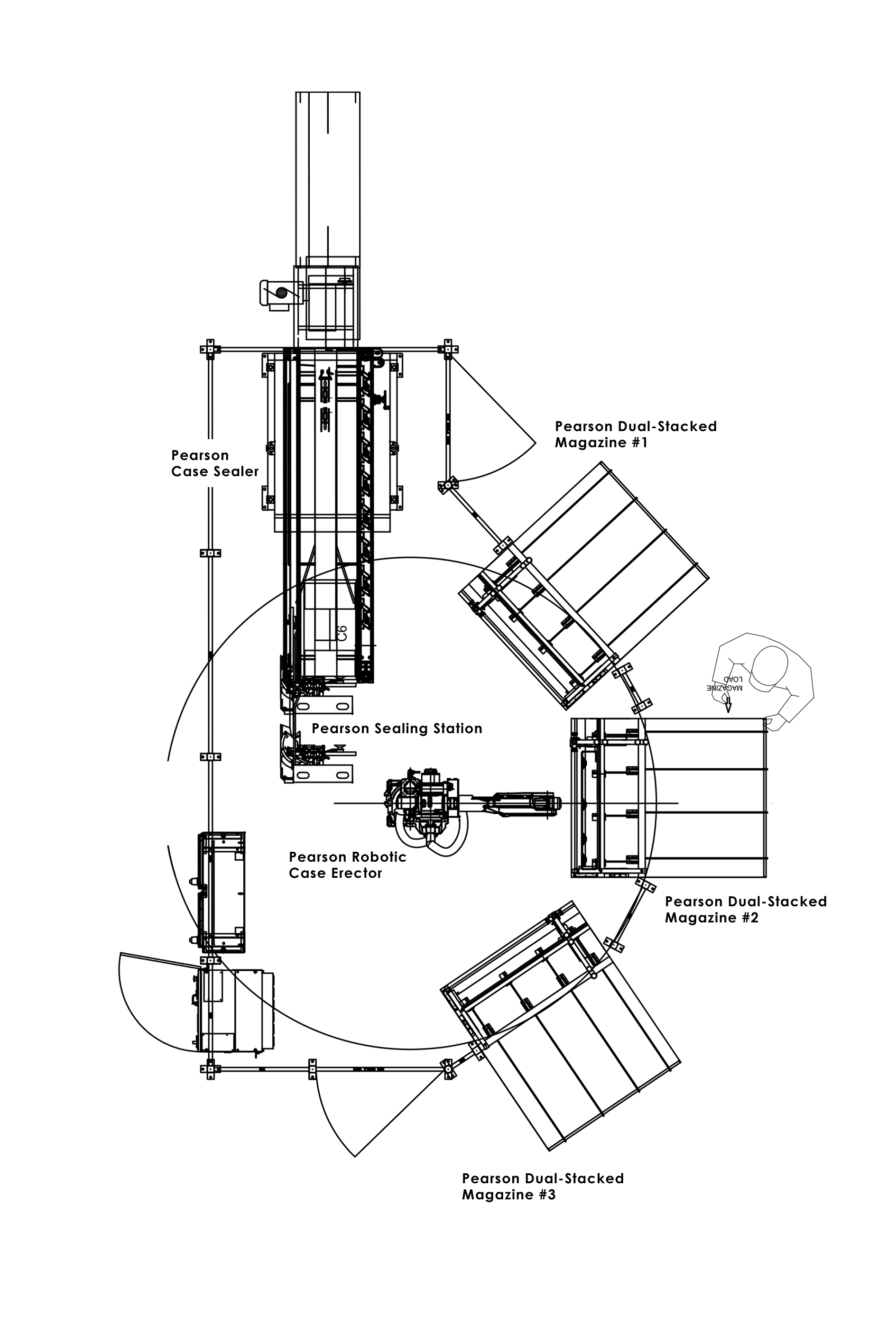

An operator dictates the robot pick logic by selecting case priority and quantity selections in the cell HMI. Using vacuum, knockdown cases are picked by the robot from one of the (3) dual-stacked powered case magazines.

The robot moves the corrugated blank to the infeed of the sealing system, where opposing vacuum cups initiate the opening of the case. Once the case is partially opened, the case squaring arm engages a minor flap kicker to provide additional squaring and support for the cases.

The cases are then indexed forward into the bottom sealer infeed where the leading minor flap is folded up into place. The dual lug synchronous drive system keeps the case square and aligned during the folding and sealing sequence, while the self-adjusting

plate applies pressure from the top for a secure tape application.

Once the designated sequence is complete, the robot will repeat the process for the next case size programmed for picking.