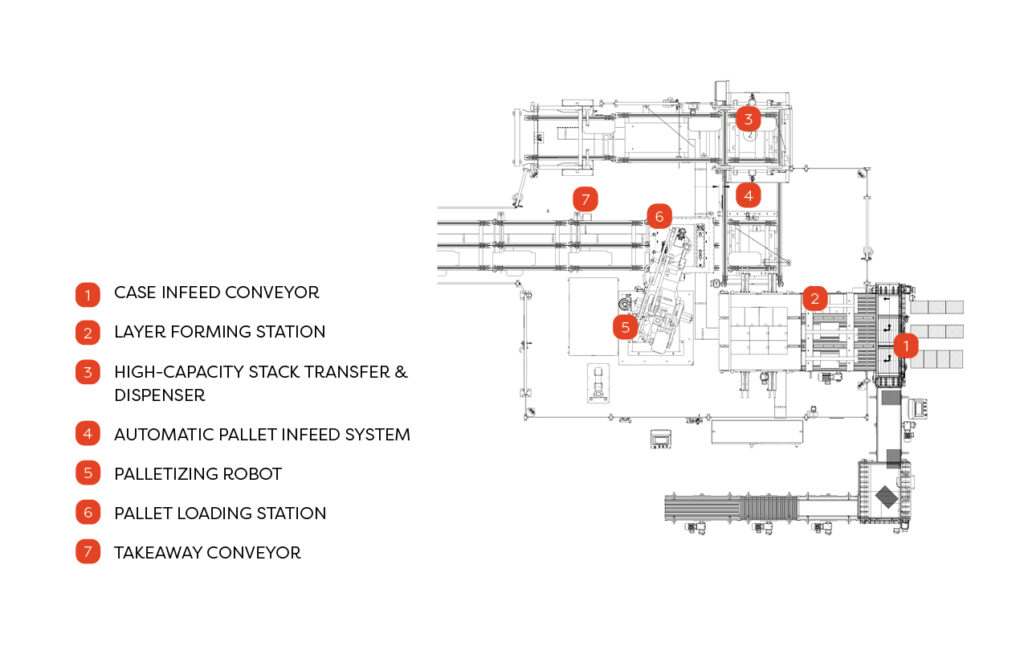

This highly safety-conscious soda syrup manufacturer was needing to replace their aging mechanical palletizing equipment to maintain compliance with their corporate safety requirements. Their aging mechanical palletizers were increasingly inefficient, and accessing them for part replacement and other maintenance work required hoists and similar equipment to reach elevated pallet build stations, elevated conveyors, etc.

The manufacturer was in need of a solution requiring less frequent pallet restocking and with a low-level infeed that would be more ergonomic for operators. They knew robotic palletizer replacements would be much safer and also more flexible compared to their mechanical equipment, and they returned to work with Pearson again after a robotic palletizing project years earlier proved hugely successful.