Packaging Automation – A Fully Integrated Solution

The goal of any packaging automation system is fairly simple to express:

At the end-of-the-day (or shift), a specific amount of product, in perfect condition, must be ready for shipment.

Not so simple is what it takes to get there:

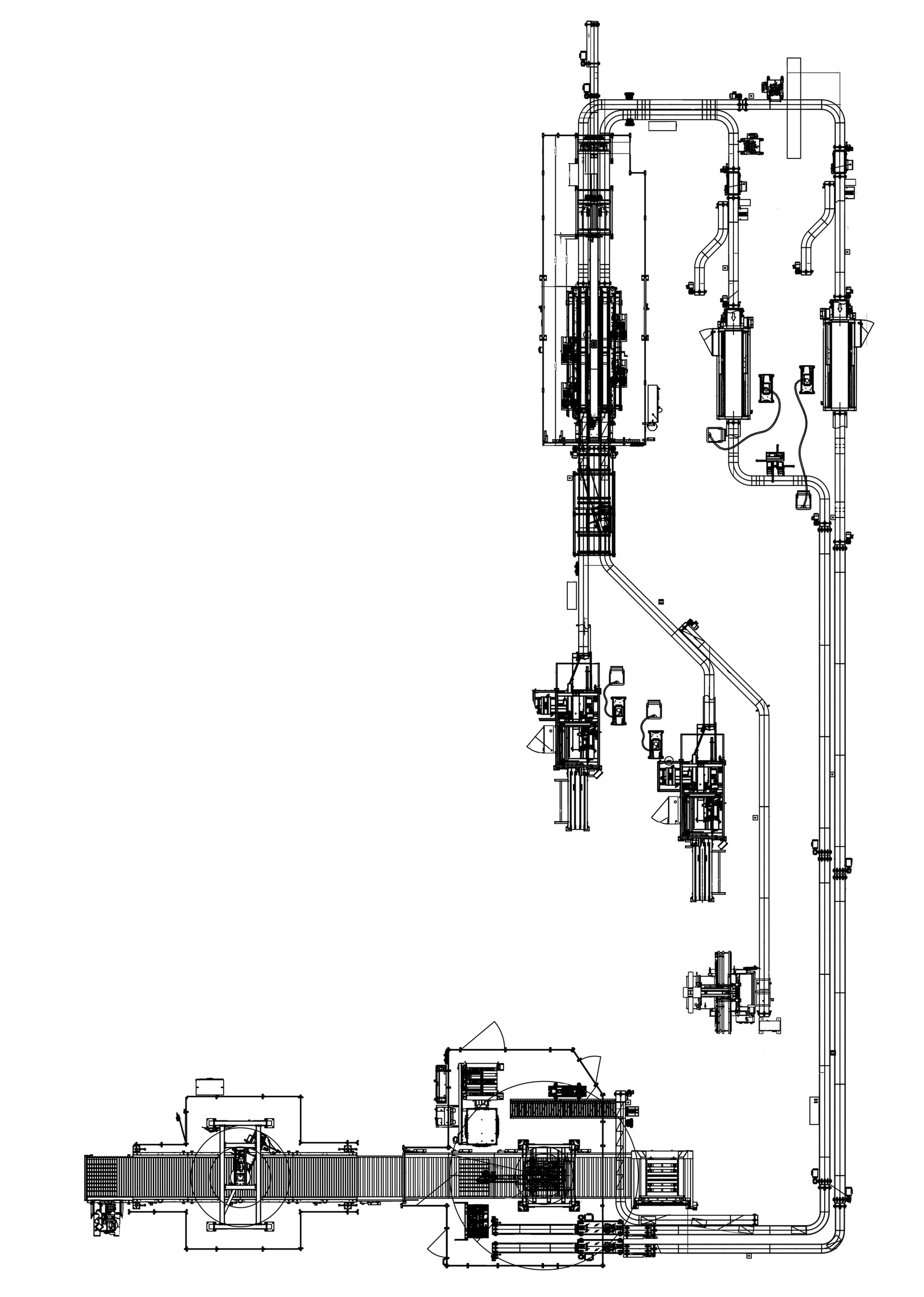

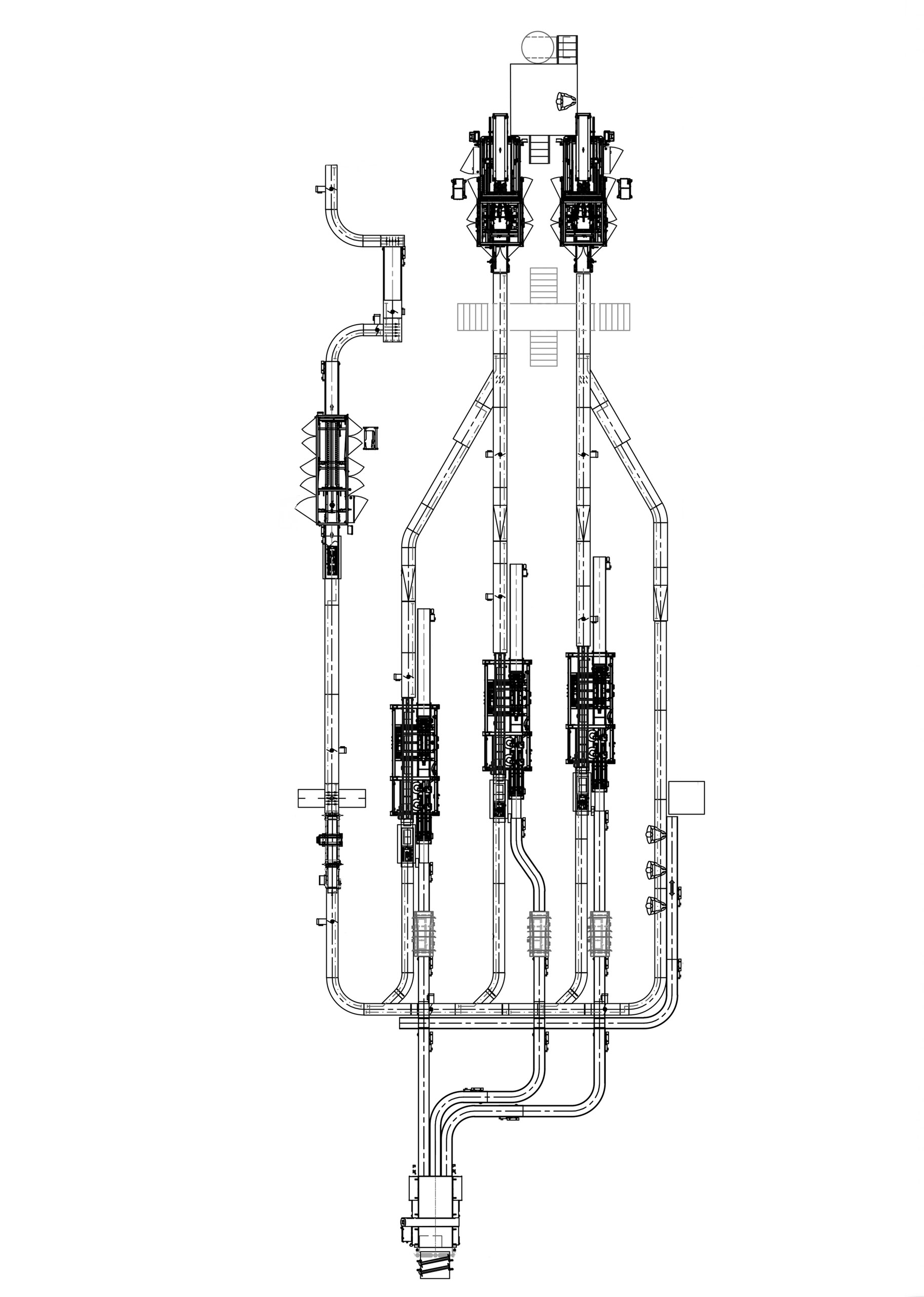

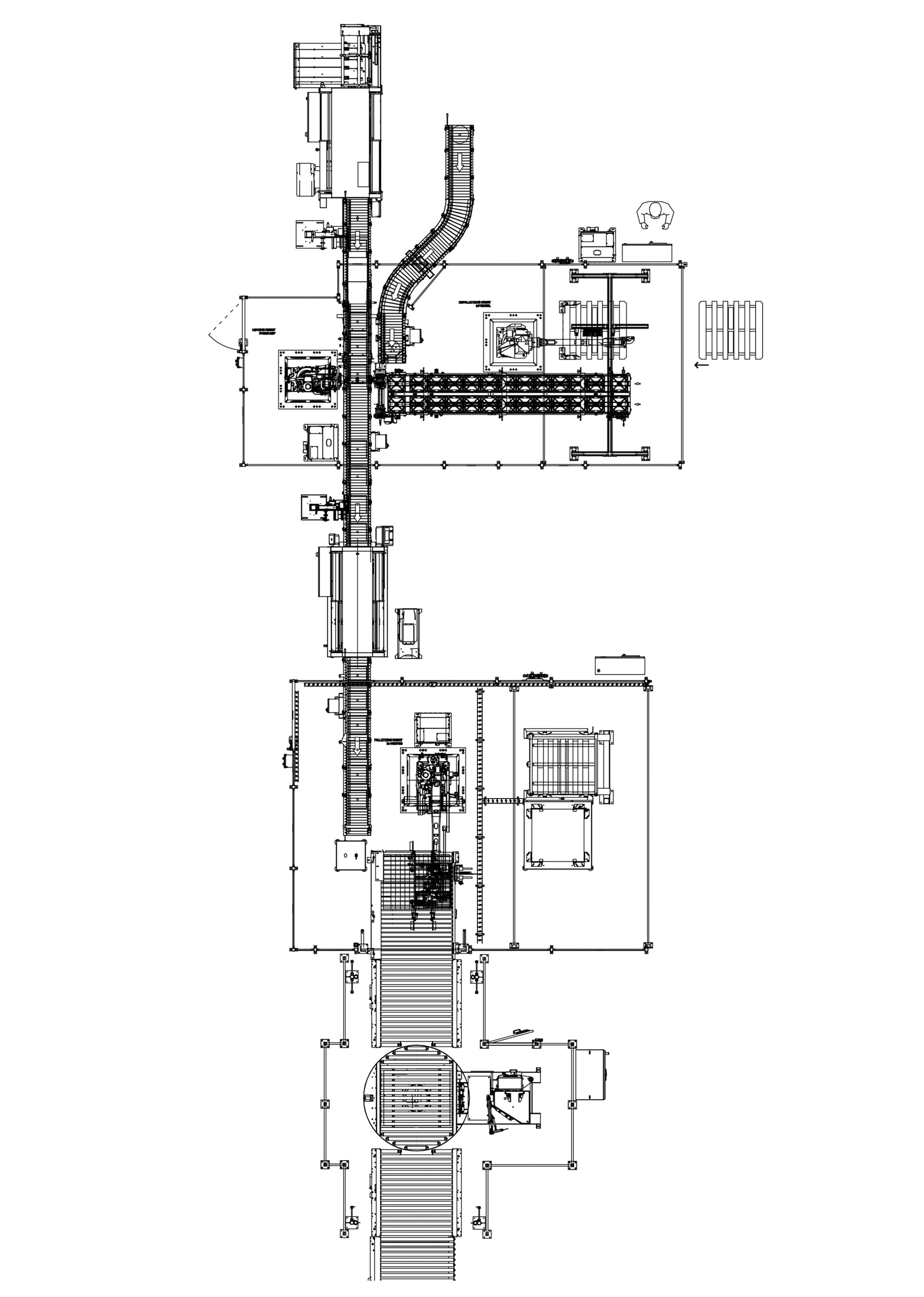

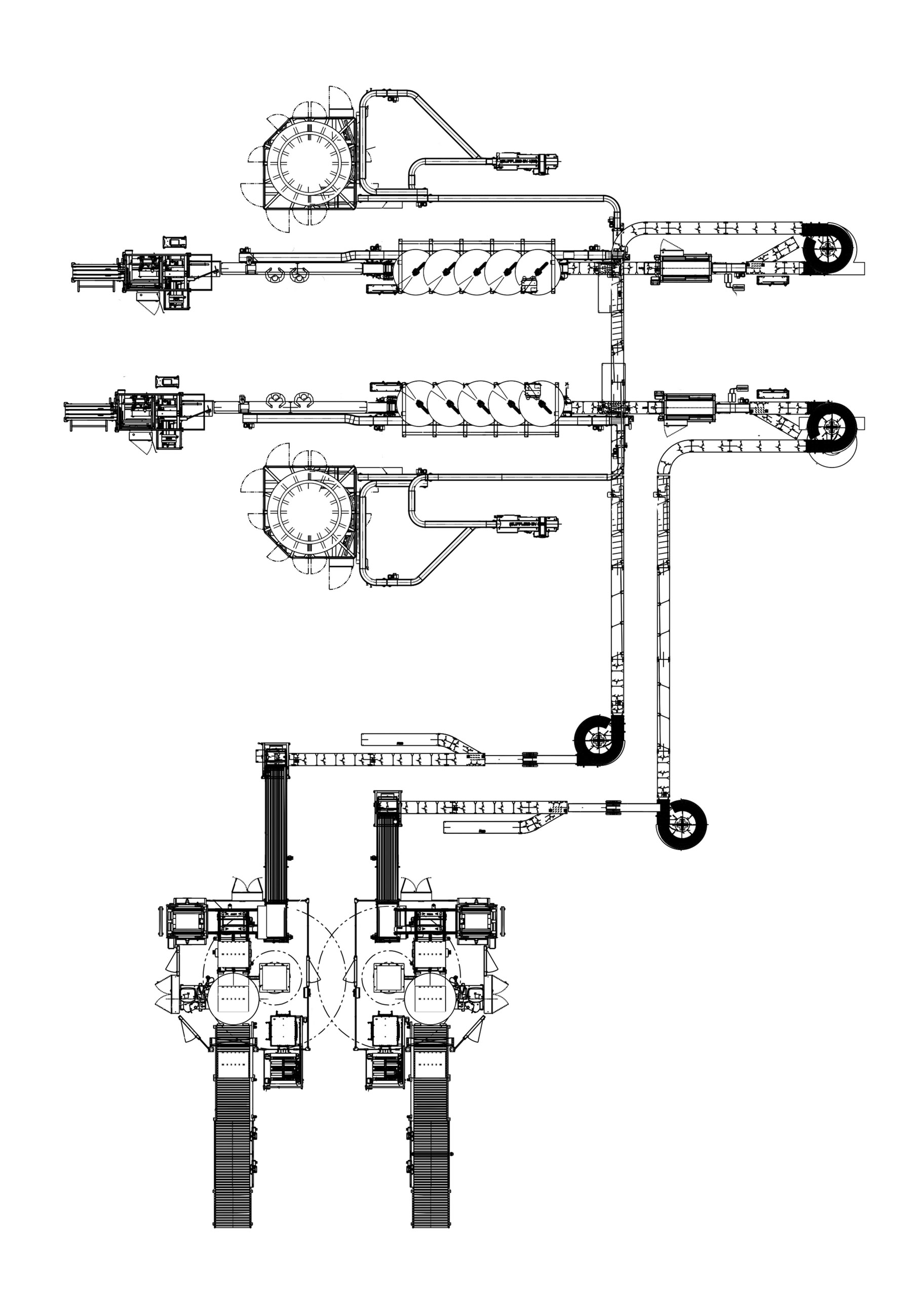

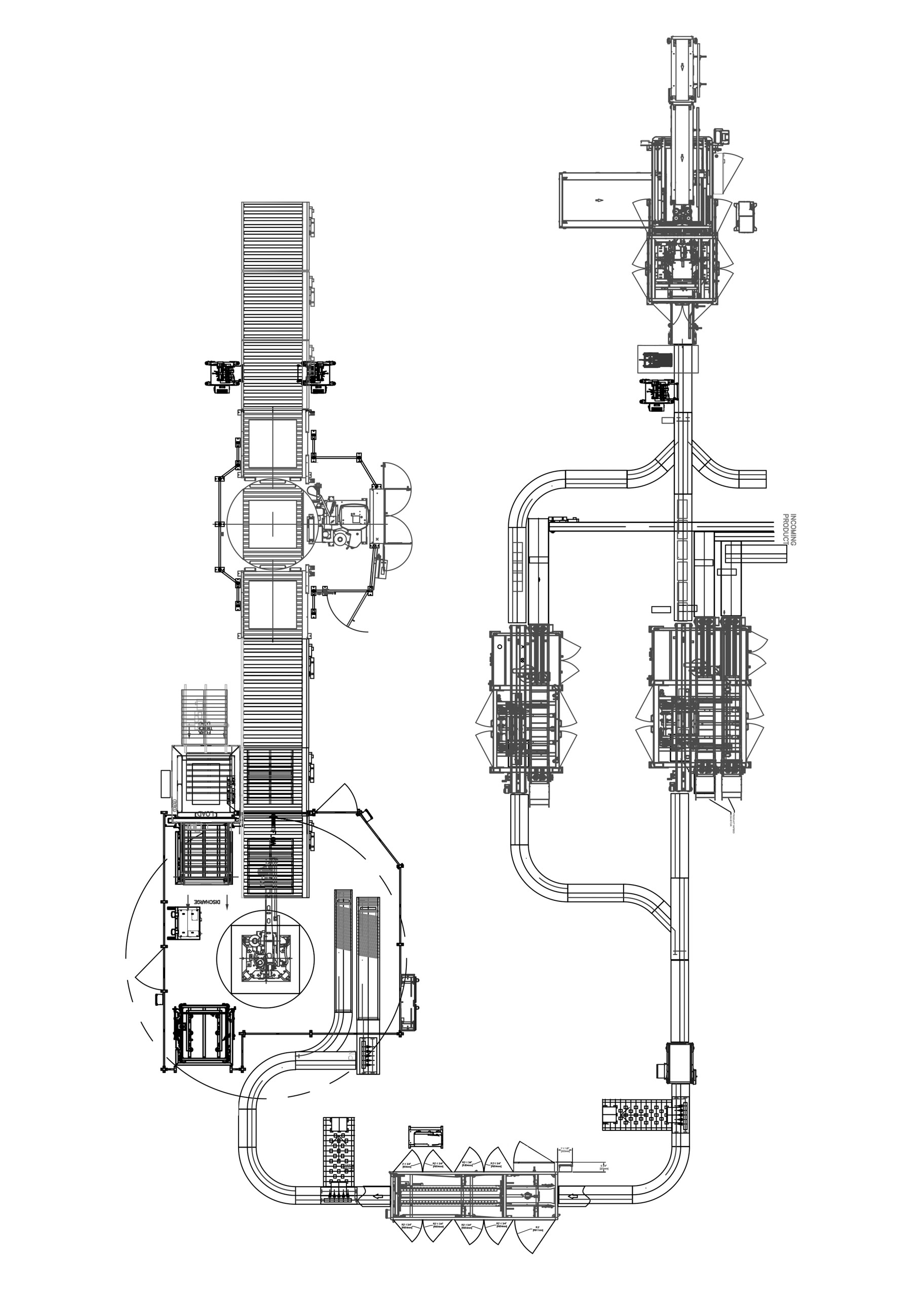

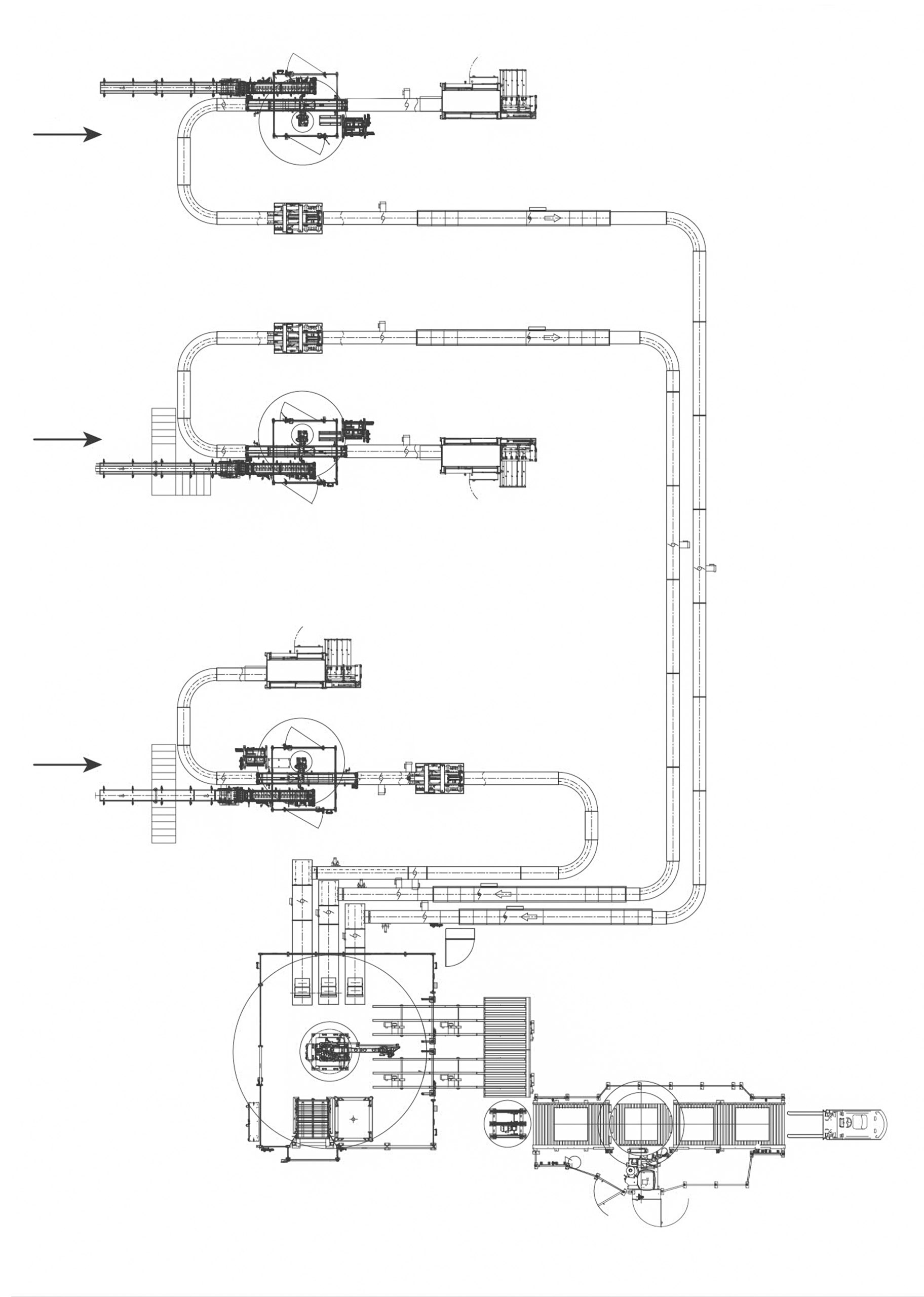

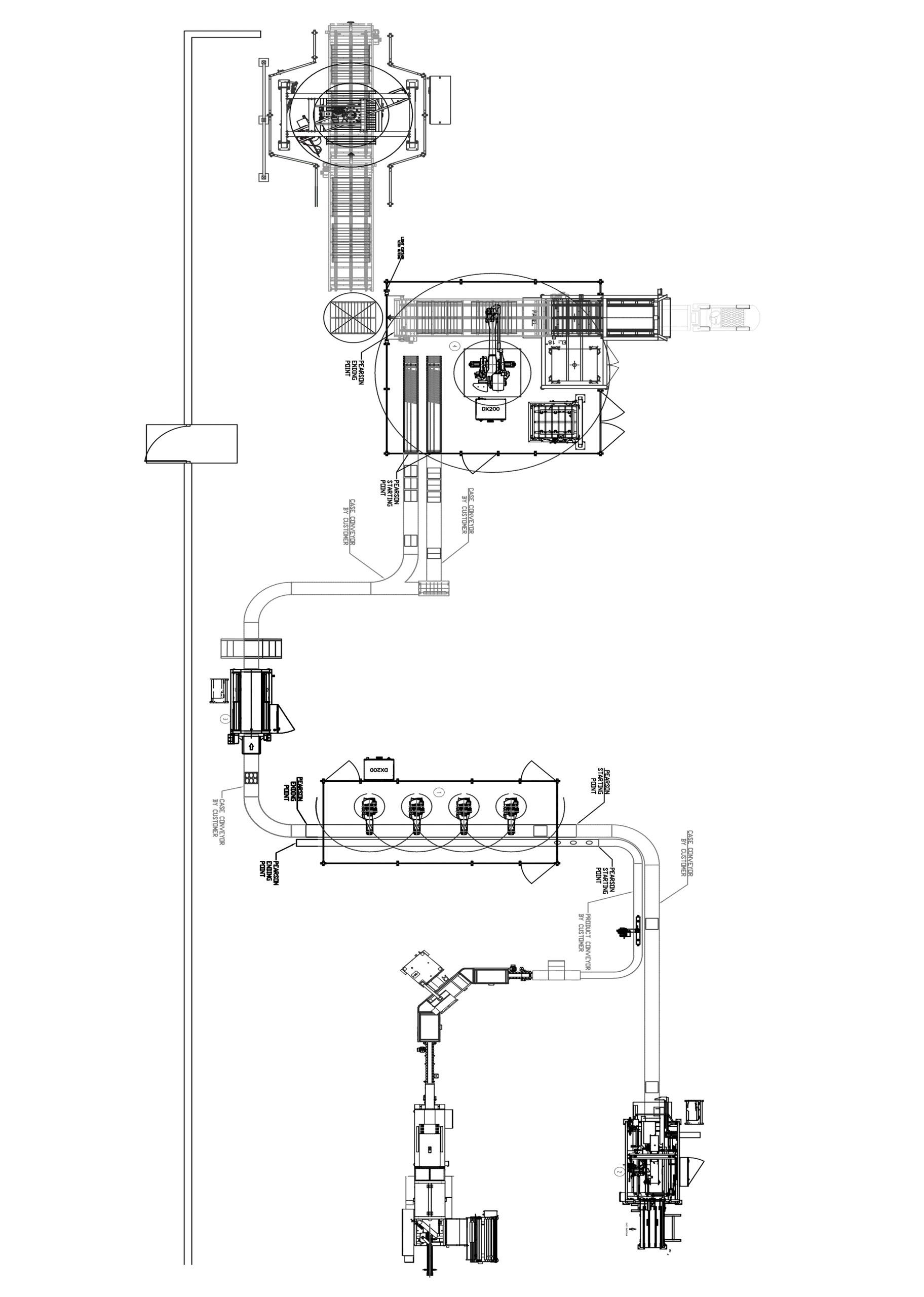

As a precisely coordinated arrangement of people, machines, conveyors, PLCs, HMIs, vision and computer systems - harmoniously working together to generate the desired throughput - any number of things can and will go wrong and affect the overall performance of the line. So the real question is not how do I get a flawlessly working system but how do I protect my throughput with an intelligent line design that anticipates challenges and mitigates against their cumulative effects? But that is not all. With so many moving parts, sourcing the right ones and bringing it all together – on-time and on-budget is no small feat either.

Choose an Experienced Partner

Systems Integration projects - with ambitious goals, concrete deliverables and substantial investments - need experienced teams. Highly specialized individuals who guide the requirement discovery process, develop practical designs and manage the implementation to meet the agreed-upon deliverables. Such experts come in many shapes - large engineering firms, integrators without OEM affiliation or OEMs who use their specialized machine knowledge as an advantage in offering integration services. Pearson's Systems Solutions Group is a unique blend of the latter two.

Having grown out of Pearson’s machine business and continuing a preferred partnership with our primary equipment supplier, we have deep knowledge of the equipment we implement and benefit from the comprehensive product portfolio, competitive lead times and strong technical support. We also remain exclusively focused on the specific area of secondary packaging line automation, but as opposed to many OEM integrators enjoy the independence of a discrete business unit to source, manage and optimize our resources according to the needs of our projects. Contact our Integration Experts