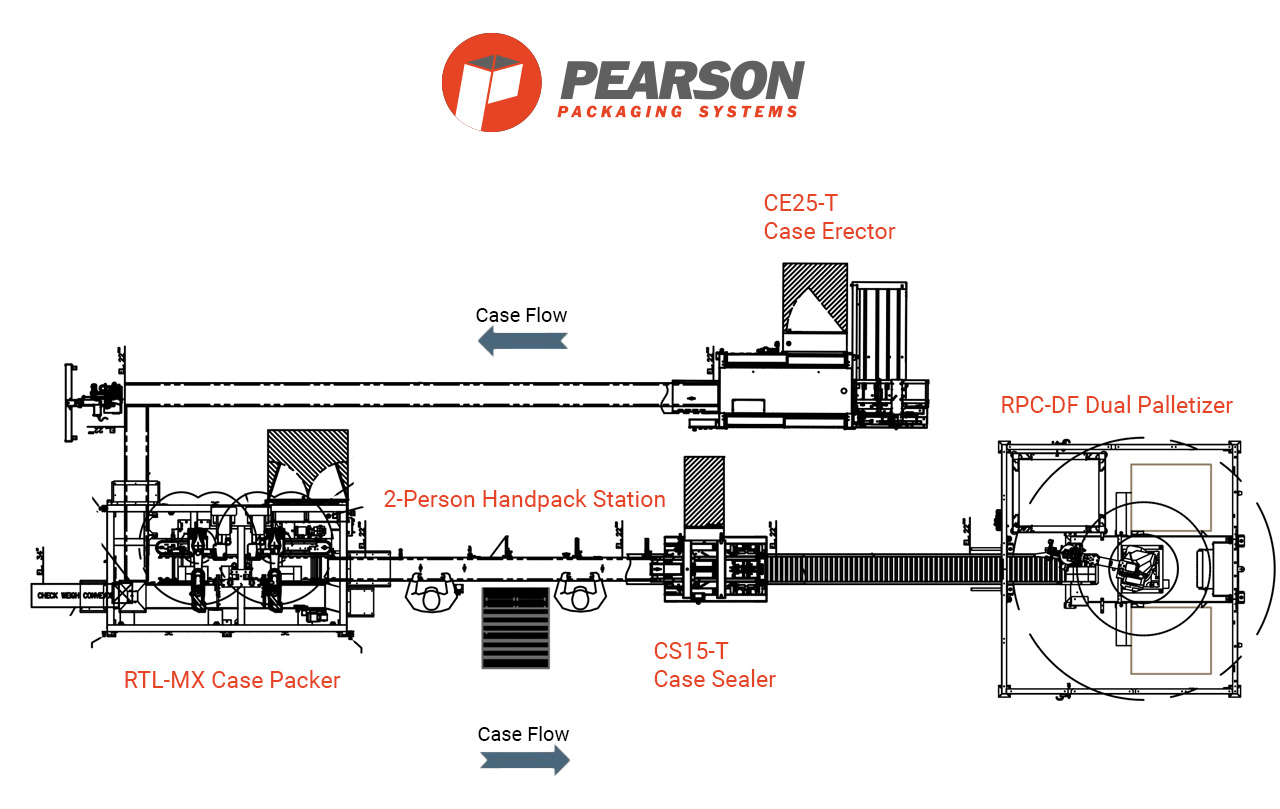

System Overview

Application: Case erecting, packing, sealing, and palletizing of bagged tortillas - 22 different SKUs / 5 different boxes

Speed: Up to 70 products per minute / 5 Cases per minute

Unique Challenge: Highly space-constrained production room

Important to Customer: Free up five operators and achieve high-speed output with consistent product handling. Flexibility to run small batches or have backup support

Description of Operation

The line includes a Case Erector, Robotic Top Load Case Packer, Case Sealer, and Robotic Palletizer.

Key system highlights include:

- Compact layout with small-footprint equipment

- 2D vision and line tracking support precise product placement

- Continuous, efficient operation is ensured by integrating a 2-person hand pack station for small-batches or additional support and a dual-floor palletizer

- The sealer's by-pass function and the palletizers multi-functioning end-of-arm tool support both, open and closed top cases

- Changeovers are fast and simple with automatic robotic adjustments and an intuitive HMI with graphical guidance to help operators easily navigate mechanical changeover points

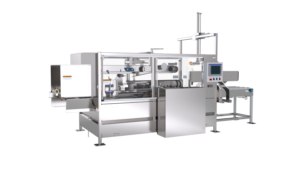

The CE25-T Case Erector automatically forms the cases. To fit into the available space, the case erector and conveying to the loading cell is positioning across from the case packer and sealer in a parallel layout.

Bags of tortillas enter the case packing cell in a single row as FANUC IR Vision registers their orientation. Simultaneously, cases enter the cell with their position being tracked for precise loading. Two SCARA robots, sharing the workload and chosen for their small footprint, pick the products and place them into the cases in a smooth motion until the cases are full and discharged from the RTL-MX. All robot motions, such as product location and placement depth into the case, are changed automatically when a new recipe is selected.

For backup support or small batch runs, an additional two person hand packing station is available and integrated into the flow of the line. Products will be received from the RTL, while cases will be brought to the operators in groups to be packed in each station and sent on to the end of the case conveyor to be transported to the CS15 Case Sealer. Using pressure-sensitive tape, this small footprint machine efficiently seals the corrugated cases. In case of open-top (HSC) cases, the sealer offers a convenient by-pass function avoiding any additional conveying.

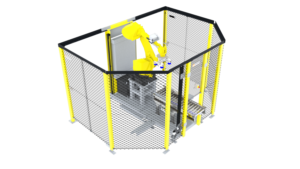

Finally, the boxes continue to the two-station palletizer, where a pallet is manually introduced by an operator with a base sheet already in place if required. After being conveyed into the pick area, the robot picks a single case using a mechanical fork style tool that accommodates both RSC and HSC cases. The case is it on the pallet according to the selected stack pattern. When required, a layer sheet is automatically picked by the robot from the integrated sheet magazines. Once the pallet is full, the robot begins palletizing on the second pallet ensuring continuous operation while an operator is being notified, who then manually removes the full pallet and replaces it with an empty one.

System Components

The soap bottle pack and palletizing system is comprised of the following Pearson machines. Click on the image to explore the standard product features interactively or visit the product page for more details.

Case Erector

CE25

Case Packer

RTL-MX

Case Sealer

CS15

Palletizer

RPC-DF

User Centric Design

User centric design is about making the interaction with our machines as intuitive as possible. All Pearson machines are equipped with a uniform user interface that is highly intuitive following common website design principles, familiar icons, interactive maps and step-by-step graphical instructions. We want to reduce the learning curve for your operators and maintenance technicians, minimize the margin for human errors and make set up, changeover and fault recovery a fast and seamless process resulting in improved up time and equipment availability.