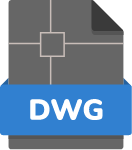

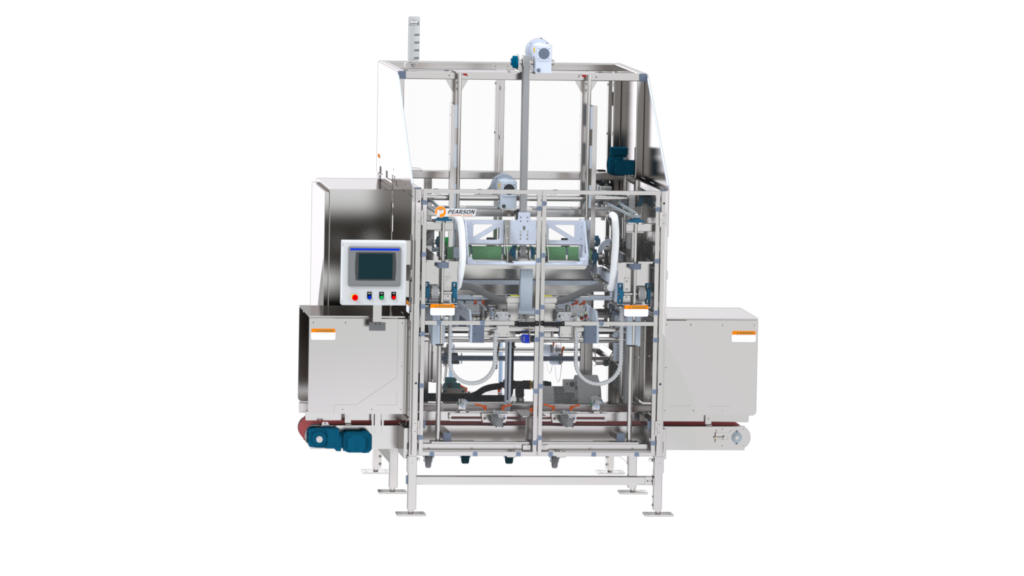

CS25-XL Case Sealer (Large Cases)

Specifications

-

Speed

- Up to 20 cases/min

- Up to 20cpm on tape models, up to 15cpm on glue models

-

Min. Case Size

- 12" (L) x 8" (W) x 6" (H)

- Range represents machine family, individual models may vary. Extended case size ranges are possible. Contact us to discuss your application.

-

Max. Case Size

- 30" (L) x 24" (W) x 26" (H)

- Range represents machine family, individual models may vary. Extended case size ranges are possible. Contact us to discuss your application.

-

Sealing

- Hot Melt Glue

- Tape

- Operation Pneumatic

-

Changeover

Manual, supported by HMI graphical guided instructions and changeover map, scales, pointers, and quick release handles

4 min (estimate for trained technician) -

Construction

- Low Pressure Washdown

- Mild Steel

- Stainless Steel

-

Machine Size Range (ft)

- 13 (L) x 5 (W) x 6 (H)

-

Controls

- Allen-Bradley CompactLogix PLC

- Allen-Bradley OptixPanel 2800 Color HMI

- PackML Compliant

- Air Requirements 80 PSI

- Power Requirements 460 VAC

- Disconnect Sizes 30 Amps

-

Air Consumption

Glue: 0.178 SCF/Cycle

Tape: 0.197 SCF/Cycle -

FLA (Full Load Amp) of Base Machine

Glue: 16 Amps

Tape: 5.1 Amps -

Case Support

-

RSC

-

User Centric Design

User centric design is about making the interaction with our machines as intuitive as possible. We want to reduce the learning curve for operators and maintenance technicians, make it easy to interpret data from the machine into actionable information, minimize the margin for human errors and make set up, changeover and fault recovery a faster and more seamless process resulting in improved up time and equipment availability.

Popular Upgrade Options

Additional Tape Head

A spare tape head allows quicker replacement of tape by exchanging the entire head and refilling the empty one while the machine is back up and running.

Air-Conditioner

Air conditioning provides cooling when ambient temperature becomes too hot or the contents of the electrical enclosure generate heat that risk failure to components.

Auxiliary Operations Station

An auxiliary operator station enables easy access to cycle start/stop, reset, and emergency stop pushbutton functions on both sides of the machine.

Bottom Tape

Bottom tape seal can be combined with the standard top tape seal. When cases arrive at the machine the bottom flaps must be closed.

Glue on Demand System

A tankless glue system pulls hot melt adhesive in solid state form from a storage container into a heat chamber where it is melted only when required. This reduces char and waste and eliminates the need to fill a melt tank that is extremely hot.

Grace Port

A grace port provides convenient communication access and a 110V convenience outlet at the outside of the machine’s electrical cabinet.

Hand Pack Station

An ergonomically-designed, highly-configurable hand pack station that can be customized for various plant layouts and output requirements.

High-Capacity Adhesive Feeder

Adhesive fill systems monitor and maintain proper adhesive levels in hot melt glue system tanks. The sealed melter and auto-feed systems relieve machine operators from continuously refilling the tank.

Low or High Temperature Package

Electrical enclosures located in cold and humid environments maintain better performance and longevity with the addition of a heater and drier package. In high-temperature environments, the addition of an air conditioner may be necessary for optimal performance.

Oversized and Undersized Case Support

This machine can be modified to operate outside of standard specifications to accommodate smaller or larger dimension products and cases. Specific adjustments require engineering review to determine limitations and potential performance trade-offs such as machine speed or larger machine footprint.

Plant Level Ethernet Connection

A Network Address Translation device allows specific Ethernet network configurations across multiple machines in the plant network and offers the ability for remote support through VPN connections.

Portability

Easily move or reposition a machine on the production floor with the portability package, which provides locking casters and stabilizing jackscrew assemblies. Depending on machine model, it can also include quick disconnects for air lines and electrical lines.

Remote Access Router

A remote access router mounted in the electrical cabinet allows secure Internet VPN connection to a machine or system for support and control program change needs. This capability is included with every Pearson engineered system and as an option on all individual machines. Remote service access offers the potential to reduce on-site service trips. Internet connectivity is available via direct Ethernet, Wi-Fi, or cellular methods.

Videos

- Hot Melt Adhesive and Industrial Machine Tapes

- Wide Range of OEM Verified Formulas

- Competitive Pricing

- Extended 1-Year Warranty for Your Pearson Equipment

Not Just a Good Product but a Reliable Partner

- Rugged machine design optimized for durability in a 24/7 environment

- Uniform user interface across the entire product portfolio

- Intuitive Human Machine Interface (HMI) to support a high-turnover labor force

- Reliable, thought-out solutions based on nearly 70 years of experience

- Comprehensive sales, aftermarket, and service support

- Large team of extensively trained technicians to service your equipment

- 24/7 live service support

- Premier industry lead-times for faster delivery and shorter down-payment cycles

- Team of project managers provides ongoing visibility to meet delivery timelines and budgets