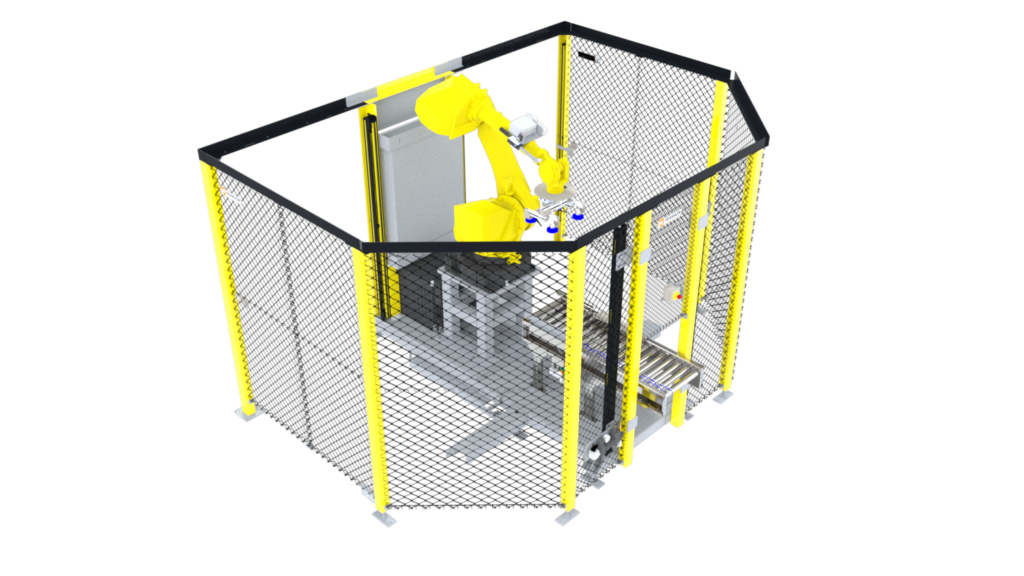

BF25 Bliss Former

Specifications

-

Speed

- Up to 25 cases/min

- Speed depends on bliss size

-

Min. Case Size

- 9" (L) x 8" (W) x 5" (H)

- Extended case size range available. Contact us to discuss your application.

-

Max. Case Size

- 25" (L) x 25" (W) x 14" (H)

- Extended case size range available. Contact us to discuss your application.

-

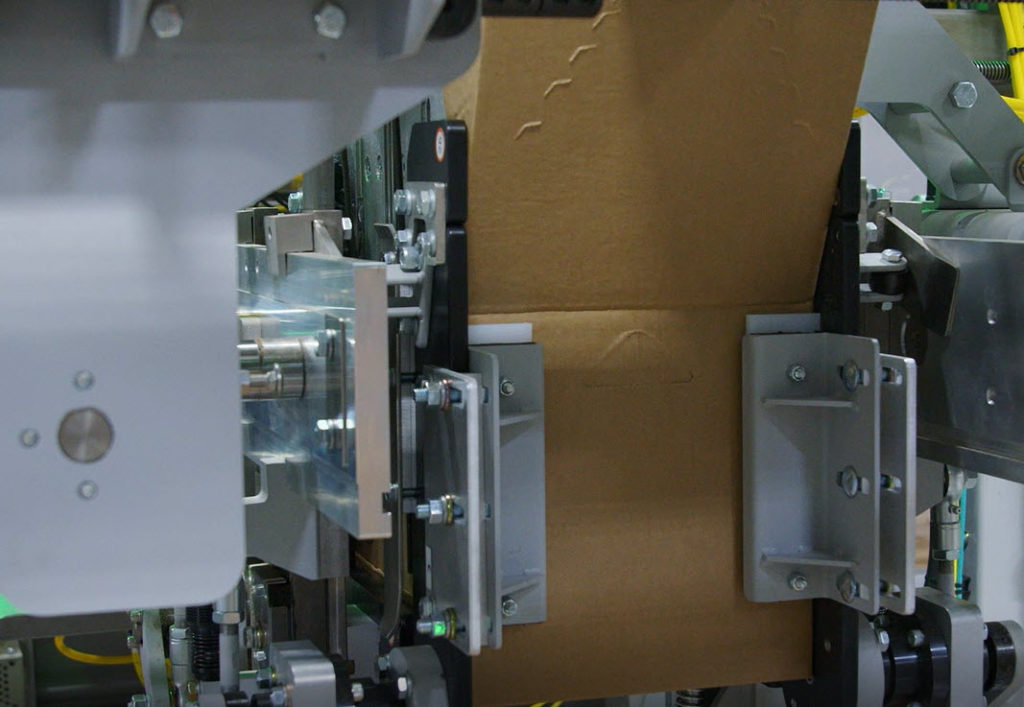

Sealing

- Hot Melt Glue

-

Changeover

Manual, supported by HMI graphical guided instructions and changeover map, scales, pointers, and quick release handles

45 min (estimate for trained technician) -

Construction

- Low Pressure Washdown

- Mild Steel

- Stainless Steel

-

Machine Size Range (ft)

- 14'6" (L) x 6'1" (W) x 10'8" (H)

-

Controls

- Allen-Bradley CompactLogix PLC

- Allen-Bradley OptixPanel 2800 Color HMI

- PackML Compliant

- Air Requirements 80 PSI

- Power Requirements 460 VAC

- Disconnect Sizes 60 Amps

-

Air Consumption

1.957 SCF/Cycle

-

FLA (Full Load Amp) of Base Machine

35 Amps

-

Case Support

-

Bliss H Shipper

-

User Centric Design

User centric design is about making the interaction with our machines as intuitive as possible. We want to reduce the learning curve for operators and maintenance technicians, make it easy to interpret data from the machine into actionable information, minimize the margin for human errors and make set up, changeover and fault recovery a faster and more seamless process resulting in improved up time and equipment availability.

Popular Upgrade Options

Air-Conditioner

Air conditioning provides cooling when ambient temperature becomes too hot or the contents of the electrical enclosure generate heat that risk failure to components.

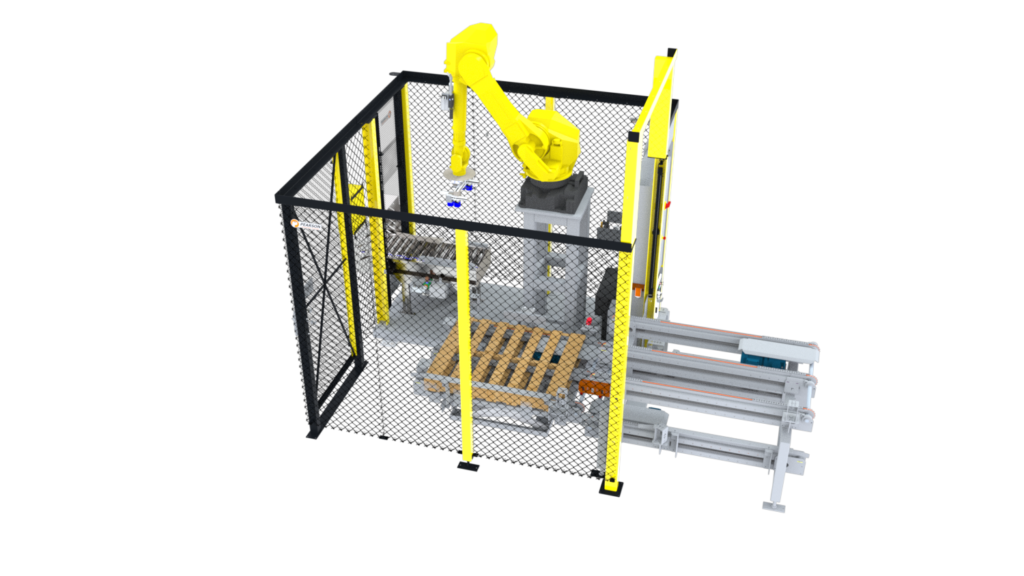

Exit Conveyor

Exit Conveyor

H-Divider Floor Lift

A conveyor coupled to an elevator system assists in loading H-divider die cut blanks comfortable from floor level, eliminating the need for machine platforms. Simplifying the loading process saves the operator numerous steps, reducing fatigue and the hazards inherent with stairs and ladders. The H-Divider Floor Loader requires the purchase of the Stack Transfer System.

High Capacity Stack Transfer System

The extended feed system replenishes the primary material hoppers. As it nears depletion, the conveyor is activated and a stack of die cut corrugate is deposited into the primary hopper. Body wrap stack transfer systems can double or triple overall material capacity, while H-divider stack transfer magazines can more than quadruple the standard machine capacity.

High-Capacity Adhesive Feeder

Adhesive fill systems monitor and maintain proper adhesive levels in hot melt glue system tanks. The sealed melter and auto-feed systems relieve machine operators from continuously refilling the tank.

Low or High Temperature Package

Electrical enclosures located in cold and humid environments maintain better performance and longevity with the addition of a heater and drier package. In high-temperature environments, the addition of an air conditioner may be necessary for optimal performance.

Plant Level Ethernet Connection

A Network Address Translation device allows specific Ethernet network configurations across multiple machines in the plant network and offers the ability for remote support through VPN connections.

Powered Scoring Wheels

For bliss former machines, powered scoring wheels help to better form case corners, reduce premature wear on the feed belt and compression rollers, and assure proper glue placement. This option is recommended for cases with display cutouts and cases with double wall body wraps.

Videos

- Hot Melt Adhesive and Industrial Machine Tapes

- Wide Range of OEM Verified Formulas

- Competitive Pricing

- Extended 1-Year Warranty for Your Pearson Equipment

Not Just a Good Product but a Reliable Partner

- Rugged machine design optimized for durability in a 24/7 environment

- Uniform user interface across the entire product portfolio

- Intuitive Human Machine Interface (HMI) to support a high-turnover labor force

- Reliable, thought-out solutions based on nearly 70 years of experience

- Comprehensive sales, aftermarket, and service support

- Large team of extensively trained technicians to service your equipment

- 24/7 live service support

- Premier industry lead-times for faster delivery and shorter down-payment cycles

- Team of project managers provides ongoing visibility to meet delivery timelines and budgets