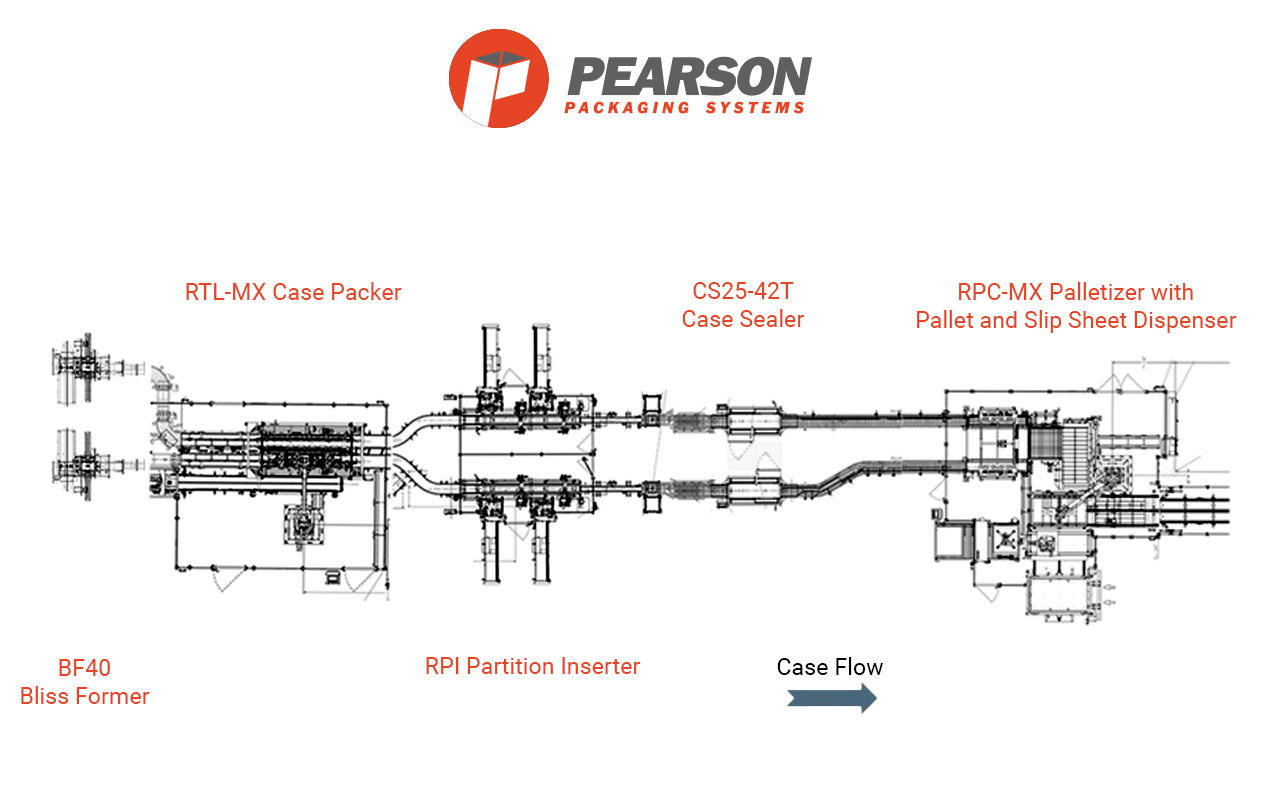

System Overview

Application: High-throughput, complete end-of-line system for jugs of laundry detergent in 2- and 4-jug tray configurations. Compatible with both display-ready trays and sealed shipper cases

Speed: Up to 120 products per minute and 60 cases per minute

Unique Challenges: Automating a high-speed packaging line within a limited footprint, without the cost or complexity of running two separate systems

Bliss Display Ready

Bliss Shipper

Description of Operation

The line includes two Pearson BF40 Bliss Formers, a RPI Robotic Partition Inserter, two CS25 Case Sealers, a RTL-MX Robotic Case Packer and a RPC-MX Robotic Palletizer.

Key system highlights include:

- Coordinated diverter, 16-bottle pick tool, and servo-driven case shuttle enable high-speed, multi-case loading, achieving 120 bottles/min and 60 cases/min with precise alignment and reliable uptime

- Servo driven side clamping end-of-arm tool picks an entire pallet layer (48” x 86”) of cases

- Partition Inserter load sharing between 4 robots to achieve high rates

- Pallet Magazine holds 15 pallets that can be loaded outside the machine guarding while the robot remains in operation

- High-speed Fanuc robots provide extremely high uptime and reliability

- Intuitive HMI uniform across entire line with interactive guides and graphical instructions for easy and fast fault recovery and changeover

Bliss display-ready and bliss shipper cases are formed on Pearson's BF40 Bliss Formers. For automated robotic case loading, a high-speed diverter paired with picking 16 bottles at a time is key to making the rate of 120 bottles/min. Case shuttle rapidly moves cases downstream, perfectly matching to the spacing of the bottles on the robot tool, resulting in high reliability and maximum uptime. A product escapement will release product to a pick station. The robot will pick 16 bottles at once from the infeed conveyor and place the product into the cases in a smooth motion. Once full, the case is released to the takeaway conveyor and the process is repeated.

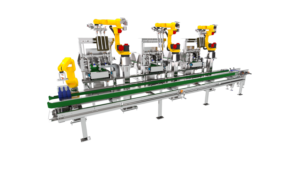

Pearson’s Robotic Partition Inserter RPI with four robots singulates individual corrugate knocked-down partitions using articulated movement, erects them and inserts them into the bliss boxes on a continuous motion conveyor at production rates of up to 60 partitions per minute. Independent left/right operation allows one side to be serviced while the other keeps running.

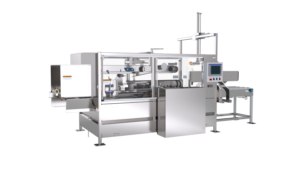

Pearson’s CS25-MX Case Sealer top seals at speeds of 30 cases per minute. A convenient bypass option eliminates the need for additional conveying when pre-sealed boxes or HSCs are introduced into the line. Display-ready trays are bypassed and go straight to the palletizer.

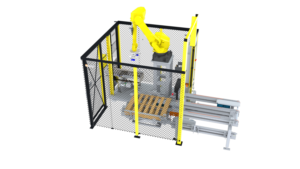

The system then moves to the robotic palletizing cell, where a servo-driven end-of-arm tool picks and places full pallet layers (up to 48" x 86") with high-speed accuracy. Dual layer-forming tables orient cases based on the pallet pattern. A second robot places slip sheets between layers without interrupting flow. Both the pallet magazine and slip sheet rack can be reloaded from outside the cell, allowing for continuous operation and improved operator safety.

Every inch of this solution was purpose-built to deliver high rates without expanding the footprint. To accommodate strict facility constraints such as building boundaries, column locations, and forklift traffic, the entire system was engineered for a compact footprint. Space-saving strategies included custom-length and non-symmetrical conveyance, compact and efficient robotic cell layouts, servo-driven pallet layer forming tables, common frames that house multiple robots or components, and optimized pick zone designs. This precision planning allowed the full system, from product receiving and case erecting to pallet output, to fit within a tightly specified floorplan.

System Components

The glass jar packaging line is comprised of the following Pearson machines. Click on the image to explore the standard product features interactively or visit the product page for more details.

Bliss Former

BF40

Partition Inserter

RPI

Case Packer

RTL-MX

Case Sealer

CS25

Palletizer

RPC-MX

User Centric Design

User centric design is about making the interaction with our machines as intuitive as possible. All Pearson machines are equipped with a uniform user interface that is highly intuitive following common website design principles, familiar icons, interactive maps and step-by-step graphical instructions. We want to reduce the learning curve for your operators and maintenance technicians, minimize the margin for human errors and make set up, changeover and fault recovery a fast and seamless process resulting in improved up time and equipment availability.

Digital Twin

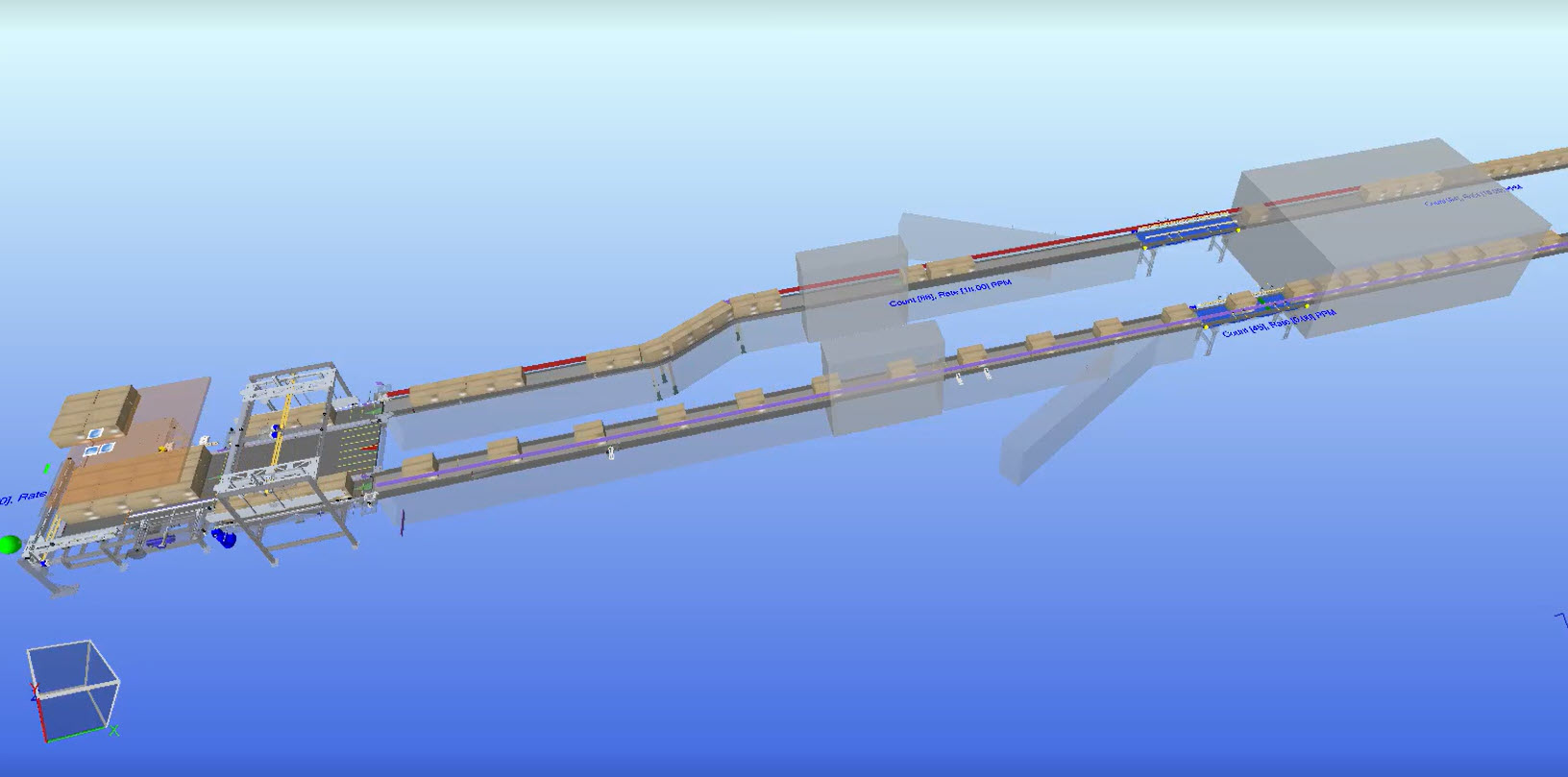

The digital twin of the laundry detergent jug line played a critical role in reducing risk and optimizing system performance.

With little accumulation across the line and the palletizer being the main bottle neck, it became the focal point of emulation. By virtually simulating the pattern-forming process, we were able to evaluate how product flow and line signaling should function to prevent faults and enable seamless stop-start coordination across the system.