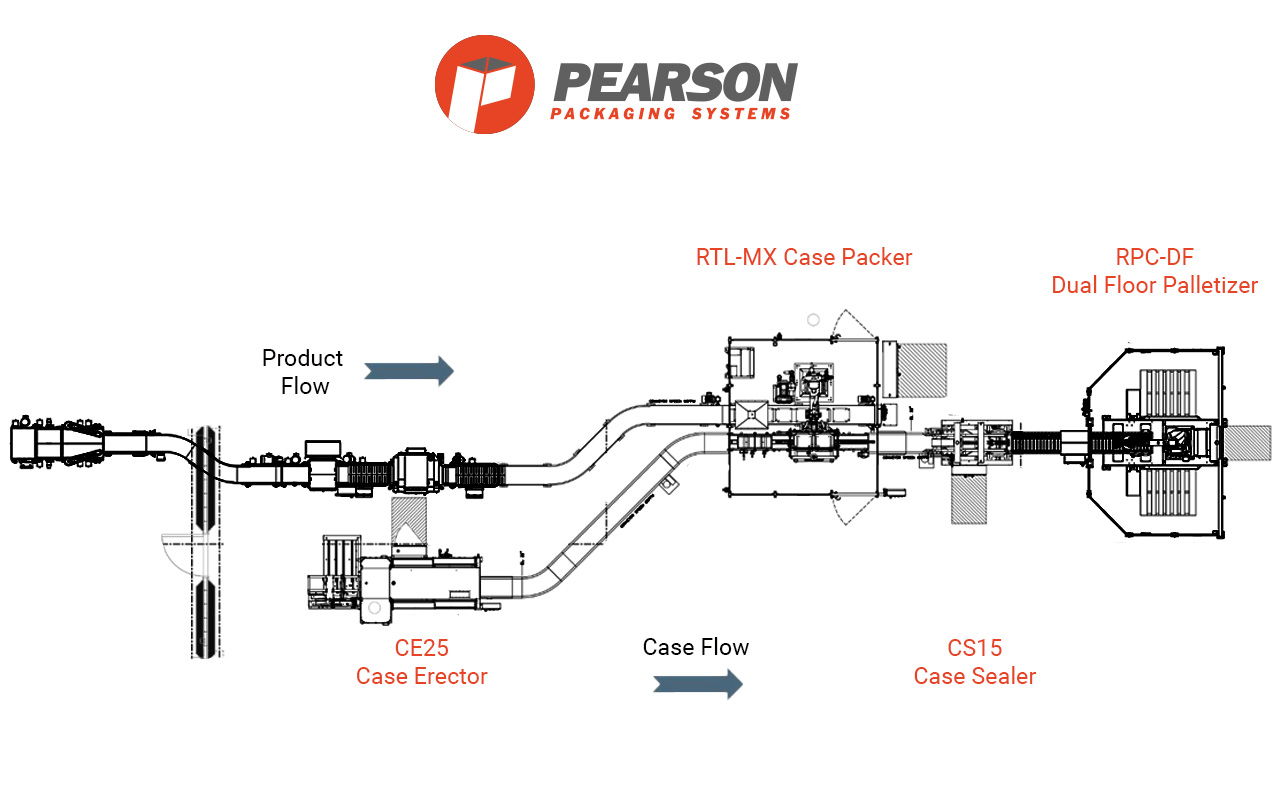

System Overview

Application: Case erecting, packing, sealing, and palletizing of trays and bags of bacon.

Speed: Up to 24 products per minute for trays / Up to 20 products per minute for bags

Unique Challenge: Highly space-constrained required precise equipment placement, and sanitation standards called for a custom stainless steel infeed conveyor

Description of Operation

The line includes a Case Erector, Robotic Top Load Case Packer, Case Sealer, and Robotic Palletizer.

Key system highlights include:

- Compact layout with small-footprint equipment

- EoAT designed for bacon products and weight range, with liquid plenum for controlled vacuum handling.

- Overhead vision system captures product position and rotation for accurate robotic pick and place

- Stainless steel infeed conveyor to meet food-grade standards

- Changeovers are fast and simple with automatic robotic adjustments and an intuitive HMI with graphical guidance to help operators easily navigate mechanical changeover points

The CE25-T Case Erector automatically forms two different case sizes, one for trays of bacon and other for bags of bacon. The machine features an inline printer mount, enabling on-demand case printing prior to forming.

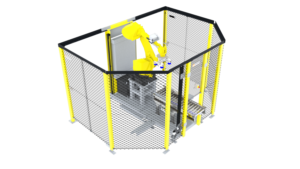

At the core of the packing operation is a Pearson RTL Top Loader, designed to handle three distinct product sizes, trays of bacon strips and 3lb-5lb bags of bacon bites. To meet food-grade sanitation requirements, a custom stainless steel infeed product conveyor was built. An overhead vision system captures the position and rotation of each incoming product. Based on recipe logic, the Fanuc robot uses this data to pick and place either one or two products per cycle into the open cases with precision. Custom EOAT with a liquid plenum system ensures smooth, sanitary, and accurate handling trays of bacon strips or flexible bags of bacon bites. Flap openers at the pack station ensure the case remains open and unobstructed during the loading process, preventing product damage or misplacement. Once the case is filled, it is conveyed out of the packing cell and transferred to the CS15 Case Sealer. Using pressure-sensitive tape, this small footprint machine efficiently seals the corrugated cases.

Finally, the boxes continue to the two-station palletizer, where a pallet is manually introduced by an operator with a base sheet already in place if required. After being conveyed into the pick area, the robot picks a single case and places in the pallet. Once the pallet is full, the robot begins palletizing on the second pallet ensuring continuous operation while an operator is being notified, who then manually removes the full pallet and replaces it with an empty one.

System Components

The bacon line is comprised of the following Pearson machines. Click on the image to explore the standard product features interactively or visit the product page for more details.

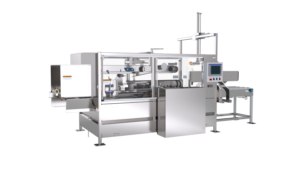

Case Erector

CE25

Case Packer

RTL-MX

Case Sealer

CS15

Palletizer

RPC-DF

User Centric Design

User centric design is about making the interaction with our machines as intuitive as possible. All Pearson machines are equipped with a uniform user interface that is highly intuitive following common website design principles, familiar icons, interactive maps and step-by-step graphical instructions. We want to reduce the learning curve for your operators and maintenance technicians, minimize the margin for human errors and make set up, changeover and fault recovery a fast and seamless process resulting in improved up time and equipment availability.