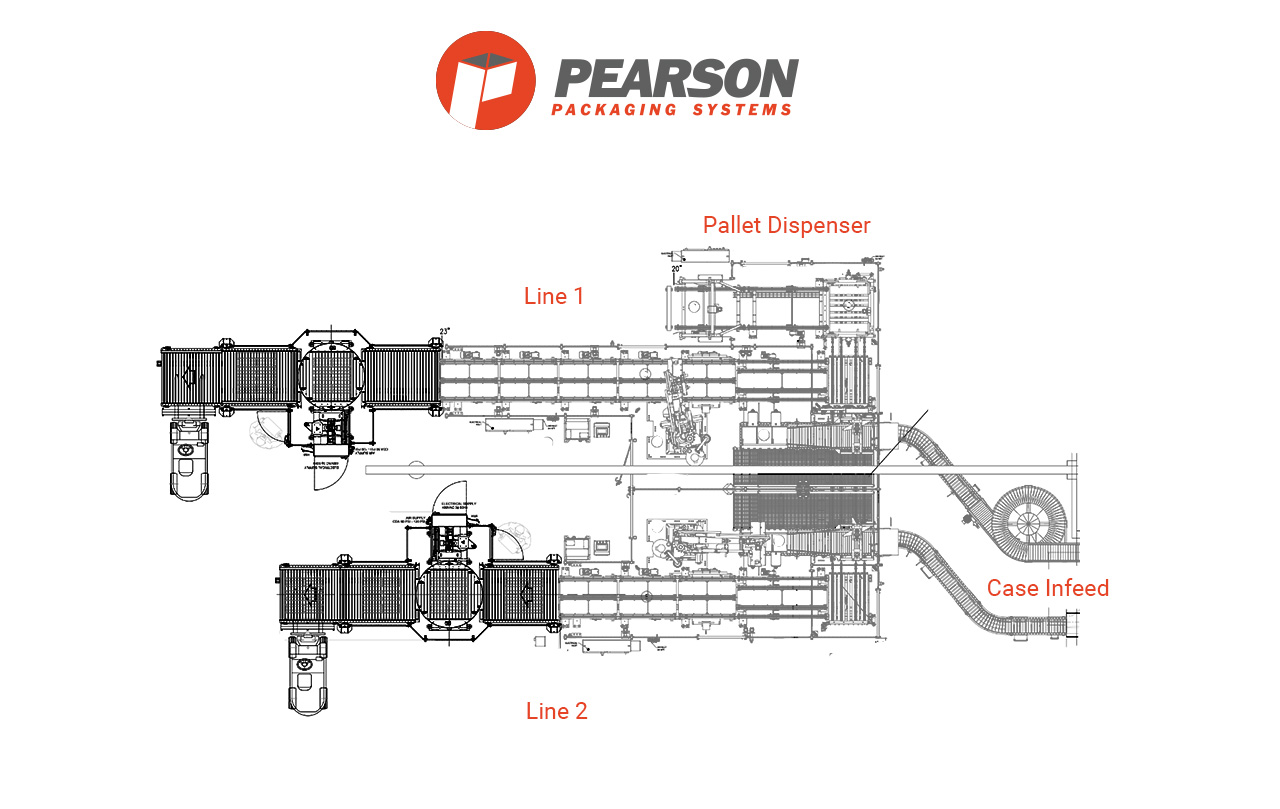

System Overview

Solicitud: Robotic palletizer for heavy 2.5 to 5 gallon syrup Bag-in-box in a highly constrained space

Velocidad: Up to 23 cases per minute for 2.5 gallon boxes / Up to 18 cases per minute for 5 gallon boxes

Unique Challenge: Automating a heavy-duty, high-throughput palletizing solution into a highly constrained space

Description of Operation

Key system highlights include:

- Case infeed with star wheel to create interlocked pattern, handles various sizes without adjustments

- End of arm tool picks and places 180-240 lb row

- Large steel baseplate is included to distribute the load from the robot onto a larger area of concrete

- Pallet dispenser accepts up to 3 stacks for a total of 42 pallets

- Diamond plates placed in between the chains along the conveyor for ease of maintenance access

An operator drops up to three stacks of 14 pallets into a shared magazine. Pallet dispenser feeds pallets to either cell, saving valuable footprint. A four drag-chain conveyor improves pallet transfer reliability when pallet quality is questionable.

2.5 and 5 gallon cases enter the cell respectively. Star wheel selectively bump turns cases according to the recipe, accumulation of 3 cases narrow-side leading or 4 cases broad-side leading to build desired pattern. This is a simple, cost-effective solution with gentle product handling for low maintenance that handles multiple case sizes without adjustments during changeover.

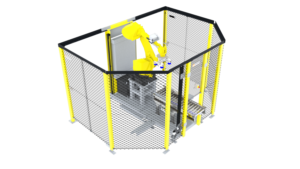

A FANUC robot equipped with a custom foam-gripper EOAT lifts an entire 180–240 lb row. Due to heavy product, a large steel baseplate is included to distribute the load from the robot onto a larger area of concrete than a standard robot baseplate. The process repeats until the full pallet is complete. Once complete, the pallet will be indexed out of the cell through the muting light curtain directly into a stretch wrapper.

System Components

The line is comprised of the following Pearson machines. Click on the image to explore the standard product features interactively or visit the product page for more details.

Palletizer

RPC-MX

Diseño centrado en el usuario

User centric design is about making the interaction with our machines as intuitive as possible. All Pearson machines are equipped with a uniform user interface that is highly intuitive following common website design principles, familiar icons, interactive maps and step-by-step graphical instructions. We want to reduce the learning curve for your operators and maintenance technicians, minimize the margin for human errors and make set up, changeover and fault recovery a fast and seamless process resulting in improved up time and equipment availability.

Digital Twin

The digital twin of the palletizer’s case infeed with star wheel allowed us to test and refine case orientation virtually, ensuring precise interlocked patterns without the need for physical adjustments during changeover.

By simulating different case sizes and line speeds, we validated performance ahead of build, reducing risk and project delays. This approach enabled products to run within two days of installation, significantly shortening overall lead time while delivering a flexible and reliable palletizing solution.