System Overview

Solicitud: Case packing and palletizing of 5 different sizes of tubs of olives. Tubs can also be stacked directly onto the pallet.

Velocidad: 120 products per minute, up to 20 cases per minute

Key Customer Challenges: Difficulty finding and retaining labor, which undermine operational security by increasing the risk of downtime, inconsistent performance, and missed production goals.

Importante para el cliente: A fully automated and dependable system that integrates smoothly with the existing Pearson case erector and sealer. Flexibility to scale for future growth.

Description of Operation

The line includes Pearson’s CE35-T Case Erector, RTL-MX Top Load Case Packer, CS25 Case Sealer, and RPC-MX Palletizer with integrated Pallet Dispenser and Stretch Wrapper

Key system highlights include:

- System Reliability: With over 80,000 hrs of Mean Time Between Failure (MTBF) Fanuc robots provide maximum reliability. Product pickup sensors verify the successful pick while case flap management removes a common snag point during case loading. The palletizer’s vacuum pump and modified blower assembly provide increased holding force using electric power, which is less costly than the standard pneumatic venturi style.

- Ease of Use: A common and intuitive human-machine interface across all machines on the line featuring Pearson’s User-Centric Design enables operators to be independently successful even at various levels of experience. The case loading and palletizing robots’ end-effectors are multi-functioning to reduce manual changepoints. A product passthrough conveyor and bypass machine function make it easy to switch from running RSC cases to stacking the tubs directly onto the pallet.

- Future Scalability: The system is designed to accept a third case loading robot for increased throughput in the future.

Cases are formed on Pearson’s CE35 Case Erector and then conveyed into the packing cell, which consists of two load stations. At the same time, products enter the system on two lanes and collate in the required configuration at each load station. The robot then picks an entire layer of product. Guides keep flaps open to ensure that the product does not snag while being transferred into the case.

A parallel path case transport system compensates for the travel distance between stations to meet required cycle times. Empty cases stop at a corner transfer, index into the case load position and once full continue to the next corner transfer that discharges them in a parallel path (under the product conveyor) to the sealer. To provide the desired scalability, the packing system offers the flexibility to add a third robot to increase production rates.

If an upstream labeler or operation experiences a temporary issue, the system automatically adjusts by delivering the product on a single lane. A diverter then separates the tubs into two lanes for both the case packer and downstream palletizer. The overall rate will be temporarily reduced until the upstream equipment is operational again. This compensation mode is automatic and only engages when needed.

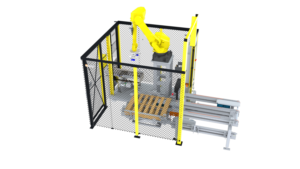

If desired, a product passthrough conveyor and bypass machine function enable the tubs of olives to convey directly to the palletizer to be stacked onto the pallet without cases. Once the cases or tubs enter the palletizing cell, they accumulate on zoned infeed conveyors and then convey into the pick area where either four cases or up to four rows of trays are picked by the robot and stacked onto the pallet according to the programmed pattern. When needed, the robot also has the capability to place layer sheets, which must be manually loaded into a static sheet rack. The rack has a low-level sensor to alert operators to the need to replenish. Pallets, whether GMA or CHEP can be loaded from the outside of the cell with a fork truck, allowing the palletizer to continue operating in the meantime.

The production line is set up to run either cases or trays at any given time, but common robotic end effectors makes switching between recipes very simple and fast, reducing manual change points. Once the pallet is complete, it conveys out of the cell through a muting light curtain and continues to the integrated stretch wrapper.

The conveyors included are designed for optimal speed control, startup/shutdown sequencing, accumulation, and comprehensive system control. Conveyors and machines are zoned for sequential control when accumulation is needed, and sequential shut down once accumulation is full. Conversely, the start-up sequence is programmed to discharge accumulation in zones to resume steady state production.

System Components

The olive tub packaging line is comprised of the following Pearson machines. Click on the image to explore the standard product features interactively or visit the product page for more details.

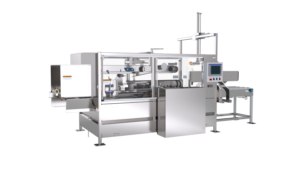

Formadora de cajas

CE35

empacadora de cajas

RTL-MX

Selladora de cajas

Palletizer

RPC-MX

Diseño centrado en el usuario

User centric design is about making the interaction with our machines as intuitive as possible. All Pearson machines are equipped with a uniform user interface that is highly intuitive following common website design principles, familiar icons, interactive maps and step-by-step graphical instructions. We want to reduce the learning curve for your operators and maintenance technicians, minimize the margin for human errors and make set up, changeover and fault recovery a fast and seamless process resulting in improved up time and equipment availability.