Your Reliable Partner for over 65 years

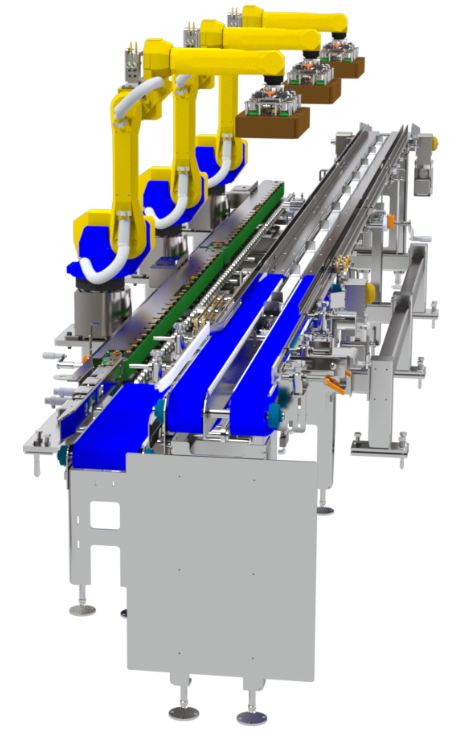

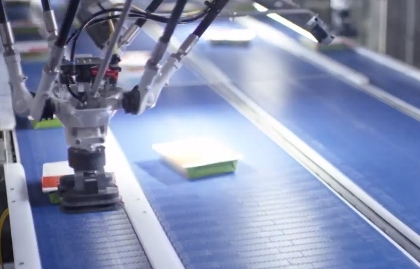

Since pack applications differ widely from one customer to another depending on the type of product, it’s unique properties, rate of speed, pack patterns, space constraints and many more factors, a one-size-fits-all solution would not deliver the results you are looking for.

In Pearson Packaging Systems you find a reliable partner with over 65 years of experience in building packaging equipment and over 30 years of integrating robots to provide fully automated systems that streamline your packing operations and achieve maximum performance with minimal downtime.

Whether you need a quote or want to explore options for your end-of-line operation, we have the solution for you.