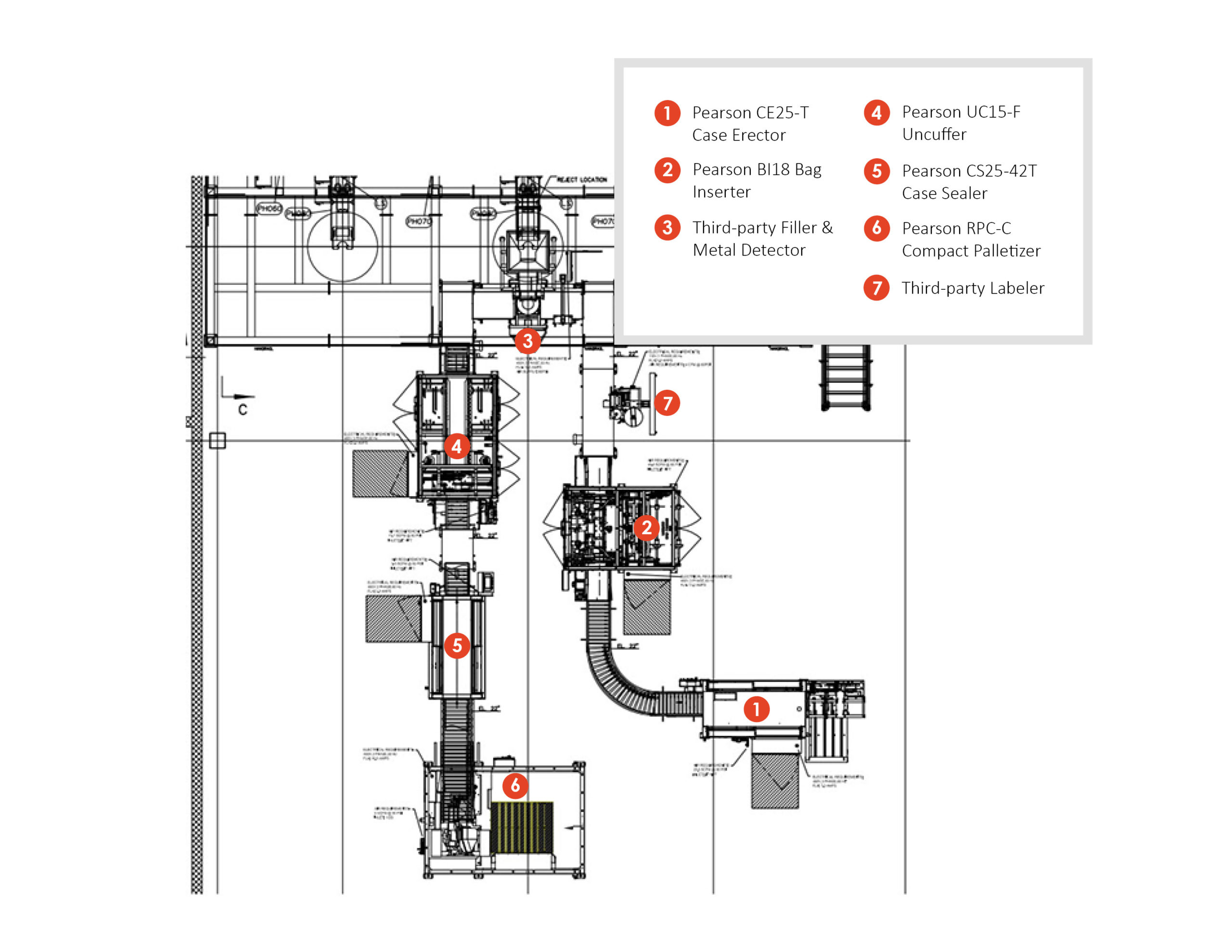

A Pearson CE25-T Case Erector uses a vertical magazine pickoff and opposing vacuum to erect knockdown RSCs (regular slotted containers). The minor and major flaps are closed and tape is applied to the bottom of the case as it translates in the machine. The erected cases are discharged upright and conveyed away.

Cases are conveyed on lineshaft roller conveyor to the Pearson BI18 Bag Inserter. Pre-perforated poly bags are singulated from a bulk roll and opened over the case. The bag is cuffed and placed into the case with an internal mandrel to ensure proper bag placement.

Cases exit the bag inserter and are transferred 90 degrees via a pop-up transfer. A Pearson purchased third-party weigh filler loads bulk snacks into the cases, and a third-party metal detector is integrated in the bulk filler to provide product inspection.

Cases exit the filler and are transferred again via a 90 degree pop-up into a Pearson UC15-F Bag Uncuffer. Bags are uncuffed from around the case flaps and gathered for folding. Folding plates engage the sides of the bags and fan fold the top of the bag.

Cases exit the uncuffer and convey to the Pearson CS25-42T Case Sealer. The top minor and major flaps are folded and tape is applied to the top of the case as it is conveyed through the machine.

Finally, sealed cases are palletized by the Pearson RPC-C compact palletizer. The palletizer features a single floor level build station for easy operator access. When a full pallet is complete, an operator removes the complete pallet load with a pallet jack or fork truck and places a new empty pallet. The palletizing cell is then reset and palletizing continues.