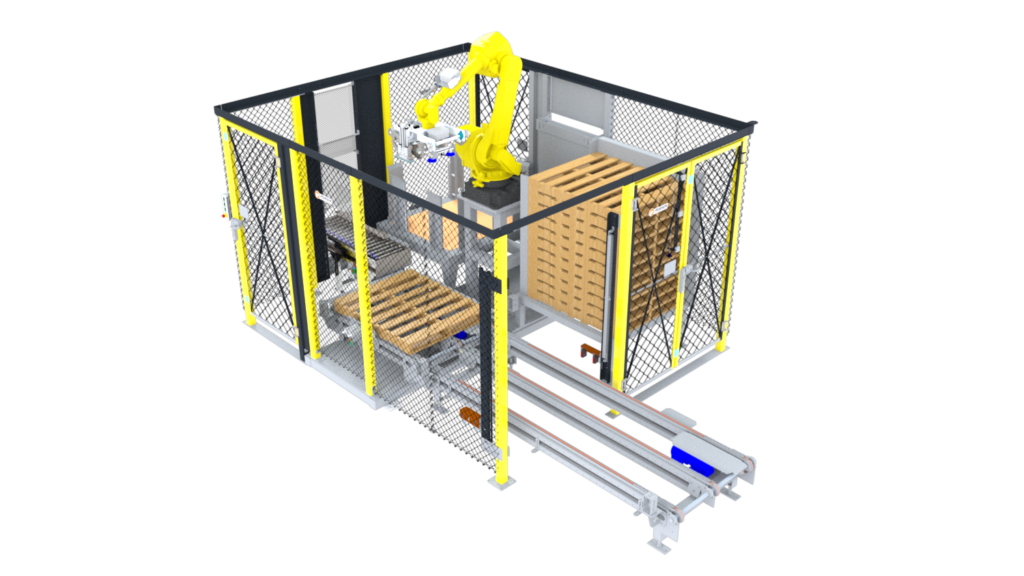

RDPC-MX Robotic Depalletizer

Especificaciones

-

Velocidad

Up to 30 products/min

*depending on pattern type, case orientation & case weight. Pick count & cell footprint may need to be modified.

- Infeed Single or Multiple Stations

- Pallet Height Up to 108 in

- Operación Robótica

-

Cambio

Easy-to-use pallet configuration tool to create, modify, copy or clear new pattern recipes on the HMI, optional automatic tool changeover.

-

Control S

- Allen-Bradley OptixPanel 2800 Color HMI

- PLC Allen-Bradley

- Controlador de robot Fanuc

- Compatible con PackML

- protegiendo Fencing, Light Curtains or Area Sensors

- Requisitos de aire 80 psi

- requerimientos de energía 460 VCA

- Tamaños de desconexión 30-60 Amps

Diseño centrado en el usuario

El diseño centrado en el usuario (UCD) se trata de hacer que la interacción con nuestras máquinas sea lo más intuitiva posible. Queremos reducir la curva de aprendizaje para los operadores y técnicos de mantenimiento, facilitar la interpretación de datos de la máquina en información útil, minimizar el margen de errores humanos y hacer que la configuración, el cambio y la recuperación de fallos sean procesos más rápidos y fluidos, lo que resulta en una mayor disponibilidad y tiempo de actividad del equipo.

Opciones de actualización populares

Automatic Pallet Handling

Automatic pallet discharge and/or pick and placement and conveying to the pick station and out of the cell.

Lector de código de barras

Also known as a barcode scanner, integrating a bar code reader enables the automatic identification and tracking of pallets and their contents, for faster processing, reduced errors, and improved inventory management.

Low or High Temperature Package

Electrical enclosures located in cold and humid environments maintain better performance and longevity with the addition of a heater and drier package. In high-temperature environments, the addition of an air conditioner may be necessary for optimal performance.

Conexión Ethernet a nivel de planta

Un dispositivo de traducción de direcciones de red permite configuraciones de red Ethernet específicas en múltiples máquinas en la red de la planta y ofrece la capacidad de soporte remoto a través de conexiones VPN.

Washdown Requirements

Upgrade package for non-caustic, non-clean environments protecting against low-pressure jets of water from all directions.