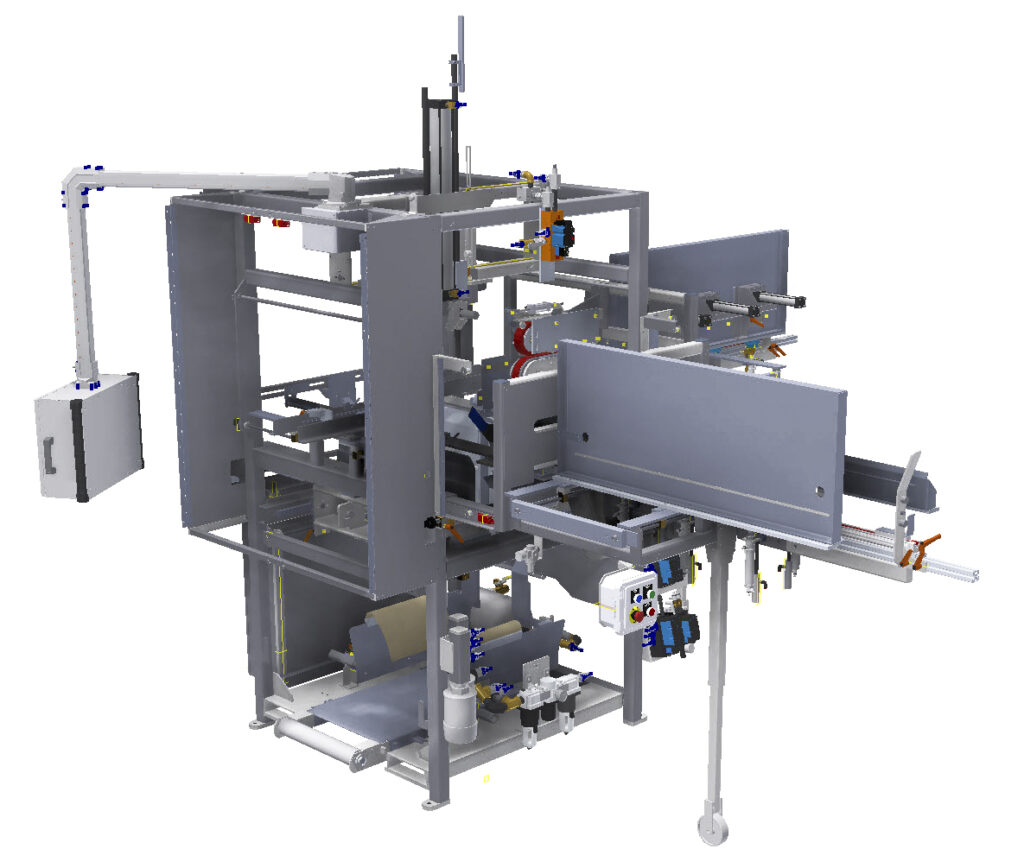

BF30-G Bliss Former

Pearson’s BF30-G Bliss Former forms sturdy shipper and display-ready box styles at rates up to 30 cases per minute. This machine is ideal for larger boxes commonly found at club-style stores like Costco or Walmart. An active forming section ensures boxes are secure and consistently square, while an intuitive HMI supports operation, changeovers and troubleshooting. An optional high-capacity Automatic Stack Transfer System is available to decrease the frequency of consumable reloading.

Erect, Pack & Seal for Bagged Tortillas

In this application, a Pearson Case Erector and Sealer form consistently square and securely sealed cases. A robotic case packer is designed with a vision system to detect the location of products, and dual Scara robots pack the products into cases. A 2-person handpack station is integrated for small-batch product runs.

Case Erecting, Packing & Sealing for Bundled Tubes

This erect, pack and seal system by Pearson Packaging Systems forms consistently square and securely-sealed cases, and incorporates a vision system and dual delta robots with custom tooling to pack bundles of personal lubricant tubes.

Random Robotic Case Erecting with 8 Magazines

This Random Robotic Case Erector can form up to 8 different case sizes based on a customer-determined pick sequence. The small-footprint cell is comprised of (4) ergonomically-designed dual case magazines that can be easily refilled while the robot is operating. An intuitive HMI supports operation, changeovers and troubleshooting. Plus, advanced features including Remote Access capability, machine status lighting and safety redundancy come standard.

RRCE Random Robotic Case Erector

This small-footprint Random Robotic Case Erector can form up to 6+ cases using a customer-determined pick sequence. It’s ergonomic magazines are accessible for refill without halting production, and it has an optional oversized case option.

CE50-UG Case Erector

The Pearson CE50-UG Case Erector is optimized to reliably form small to ultra-small and unstable cases at rates of up to 50 cases per minute. Its proven design uses servo motors on all major motions.

Running up to 50 cases per minute, this Case Erector is ideal for ultra small, irregular and standard cases.

CE35-T Case Erector

Pearson’s CE35-T Case Erector forms a variety of case styles with tape at rates up to 35 cases per minute. The machine uses dual opposed vacuums to open cases from both sides, and comes with an intuitive HMI supporting operation, changeovers and troubleshooting. Plus, advanced features including Remote Access capability, machine status lighting and safety redundancy come standard.

CE50-UG Case Erector

Pearson’s CE50-UG Case Erector forms a variety of case styles with glue – including ultra-small sizes – at rates up to 50 cases per minute. The machine uses dual opposed vacuums to open cases from both sides, and servo motors on all major motions reduce air consumption and maintenance. With an intuitive HMI supporting operation, changeovers and troubleshooting, the machine also comes with standard advanced features including Remote Access capability, machine status lighting and safety redundancy.

Case Erecting, Packing & Sealing for Juice Cups

This erect, pack and seal system by Pearson Packaging Systems forms consistently square and securely-sealed cases, and incorporates dual robots with custom tooling to pack layers of juice cups and place dividers. With a consistent HMI across all equipment to support operation, changeovers and troubleshooting, the system also comes with Remote Access capability, machine status lighting and safety redundancy.